Micropac MTE and MTE-B Pressure Test Safety Enclosures. An essential part of your equipment for safe pressure and burst testing.

Why use test protection?

Whether you are hydrostatic pressure testing to working/ proof pressure or taking a part to destruction and bursting it, there is inherent risk. Pressure is stored energy. You need to plan and protect.

If you need to revisit these pressure terms, draft a pressure test procedure, pressure test certificate or risk assess your test set-up, visit our resource.

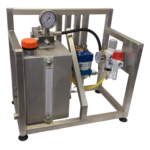

The MTE Test Enclosure is intended for use with hydraulic testing of components. The external size is 400 x 600x 200mm. The enclosure offers a degree of protection against bursting of the component under test, both from fluid and projectiles. The suitability of the enclosure to offer protection and safety of the user and others in the area must be assessed as part of the test facility design process.

Our MTE-B Test enclosure offers enhanced protection by using additional very high impact polycarbonate in its construction in line with EN DIN 12415. This Test Safety Enclosure is primarily designed to work with our own Micropac pressure test pumps or similar. Because of high levels of stored energy, a customer would have to satisfy themselves on the suitability of this equipment for high pressure gas pressure and burst testing.

Our white paper on burst test and ballistic protection offers some guidance and a background to this very real safety problem for anybody who is pressure or burst testing.

Why use the Micropac MTE Pressure Test Safety enclosure?

Protective screens are widely used for pressure testing, particularly in a shop were there is risk to operatives. There is always a limitation on coverage for screens and inevitably an issue with a fluid spill from a burst covering benches, walls and the ceiling. The MTE offers a highly cost effective enclosure that will contain fluid spillage and also provide protection as part of a customer risk assessed test set-up. Read more about burst testing basics, safety and where the MTE is used. Plus some basics on ballistic protection.

What is the difference between the basic MTE and a chamber like the MTE-B with enhanced impact resistance? At what point should I be looking at bullet proof or blast proof ballistic chambers or screens?

This is a very deep area. Read our White Paper on this subject. Our MTE-B offers a very cost effective chamber with enhanced resistance to impact from a burst of a component. The MTE-B certainly offers an effective solution for many applications. Although a “bullet proof solution” is offered by suppliers, resistance to very small projectiles with massive velocity being propelled by a rapidly expanding volume of gas may not be that relevant to your own failure modes. Bullet proof solutions will also be very expensive.

How do I connect the Micropac MTE Pressure Test enclosure for my application?

The unit allows a hose to be connected to the outside of the enclosure back to the pump then the feed to the test piece connected inside. That is safe and easy. For simplicity, the standard unit provides a G1/4 male coned pressure connection inside the enclosure. Connect your test piece to this fitting using your own short flexible hydraulic hose which in turn is connected to the test piece. If there is a bleed connection, expel all the air at low pressure before placing the test piece and connection hose into the chamber and closing the door. If you are doing repetitive testing, it may be cost effective to terminate your short hose in a quick disconnect coupling or customer quick change connector which mates with the test piece.

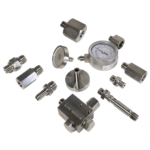

Please talk to us about options for custom pressure test fixtures for this enclose. Special fixtures and connectors have included caps for testing eco PET moulded bottles, thin wall plastic connectors for medical sample bags and a neat manifold for connecting two metal bottles, bleeding them and then testing.

Select a Micropac pressure test pump and hose to complete your pressure or burst test package. Our MP-A low cost anodised alloy/stainless units offer an easy carry-around solution, the MP-3 series offer 316 stainless and bronze for an extended service life and our MD-6 two speed pump offers a fast prefill and short test cycle. Or look at the MW-A or MW-3 hand pumps on fixed reservoirs if you want a bench test unit. If you require a test pump that will repeat a cycle up to thousands of times, look at our PTR Programmable Pressure Test unit, offering comprehensive and easy programming at a low cost compared with custom pressure test rigs.

Talk to us about drag pointer pressure gauges and electronic gauges that record a maximum reading if you are burst testing.

We have been designing and manufacturing our Micropac pressure test pumps for over 40 years. Talk to us about your application. We are the experts.

Share This!

Related Products

Technical Specifications

| Size: | 600mm x 400mm x 210mm (external) |

| Materials: | Polycarbonate,

Polyurethane rubber door gasket, 316 stainless bulkhead connection |

| Options available: | Adaptor fittings on bulkhead connections,

Hoses available to order |