How a Risk Assessment for Pressure Testing is an essential first step.

We have provided here a typical Risk Assessment for Pressure Testing. Just like every other activity in the workplace, you must assess risk. Because we are using a pressurised system, there are real risks through failure of the test piece, the system itself or misuse through misunderstanding or abuse. Addressing all the risks through a Risk Assessment for Pressure Testing is essential.

Our Risk Assessment for Pressure Testing reproduced here is for guidance only and your document will need to meet your needs and environment.

| DATE OF RISK ASSESSMENT | COMPANY NAME | ||||||

| EQUIPMENT LOCATION | |||||||

| COMPILED BY | AUTHORISED (SIGN) | ||||||

| IDENTIFICATION OF HAZARDS |

| Rupture of pressurised system during operation of the hand pump, potentially causing injury to operator or bystanders, and damage to surrounding equipment/ working environment

Use in a safe working environment |

| CONTROL MEASURES | ||

| CONTROL | REQUIREMENT | ASSESSMENT OF COMPLIANCE |

| PPE | Wearing of safety glasses for operator and those in the working environment mandatory.

Refer to COSHH assessment for hydraulic media in use and wear gloves, overalls and any other PPE as applicable. |

|

| Working environment | Unless ATEX certified by SHL, the equipment is not suitable for use in any category of potentially explosive environment. | |

| Access | Ensure that unauthorised access to the working environment is prevented whilst testing is in progress. | |

| Equipment | Ensure that connection adaptors are the correct thread- refer to O&M manual for connection to SHL equipment.

Ensure that any flexible hoses or pipework are suitably rated for maximum working pressure, are compatible with the intended hydraulic media, and are in good condition e.g. not kinked, and suitable for use in accordance with the manufacturer’s recommendations for working life. |

|

| CONTROL MEASURES | ||

| CONTROL | REQUIREMENT | ASSESSMENT OF COMPLIANCE |

| Equipment continued | Position unit under test such that projectiles cannot cause injury to operator or bystanders, or damage to the surroundings.

Ensure that any requirements for guarding against over-pressure are observed. In some cases, the over-pressure device must comply with the requirements of the PED or other regulatory requirement. Note- the optional SHL built-in relief valve is not PED-certified. If in doubt, contact the factory. Review your test set up against the PED in the EU. The test pressure, the test volume and the nature of the test fluid will determine whether you are working within “Sound Engineering Practice.” In the EU, you must work to this standard. |

|

| Information, instruction & training | Read the SHL operating instructions before use and ensure that instructions are followed. Ensure that operators are trained in using the equipment and made aware of all risks pertaining to safe use as identified in this risk assessment.

Ensure that SHL equipment is correctly sited and that operators check condition of hoses, fittings etc before commencing testing. Ensure all persons in the working environment are suitably protected from flying debris and hydraulic media in the event of rupture. |

|

| Maintenance | SHL equipment complies with the requirements of the Pressure Equipment Directive (PED), and the user shall ensure that the equipment is inspected and maintained in accordance with the operation & maintenance (O&M) manual.

Ensure all other equipment external to SHL unit is regularly maintained, inspected, tested and calibrated in accordance with manufacturer’s procedures or as defined otherwise. |

|

2018 Sarum Hydraulics Ltd

007065000 Risk Assessment Micropac Test set issue 2 Page 1 of 2. Example for guidance only.

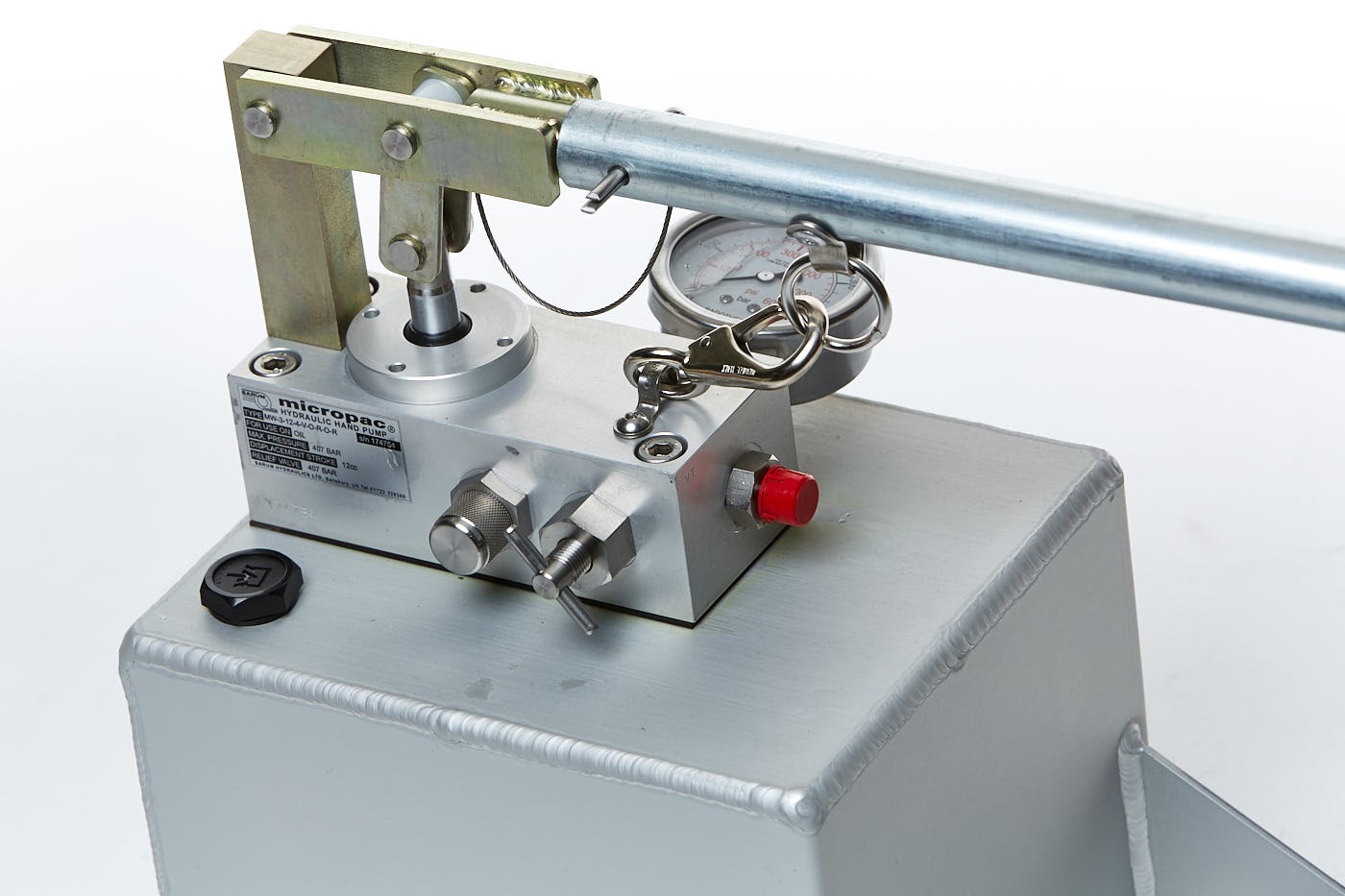

Micropac hydrotest pump

You may also be interested in;

Our ten tips to make a hydrostatic pressure test easy. What we have learnt over 35 years.

How to Hydrostatic Test including a sample procedure.

Our You Tube video “how to burst test” shows a Micropac pump used for a simple but safe burst test.

Leave A Comment