Micropac hand pump units are used all over the world for charging, filling and lubrication.

Pumps from our standard range are suitable for these applications. Durable and low corrosion designs ensure that equipment is reliable even in demanding environments. Our long standing expertise with multiple fluids, operating conditions and seal compounds will provide an economic pump unit for your application.

Units feature poppet and soft seat check valves for very low leakage and good pressure holding.

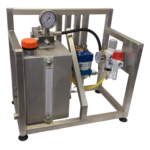

If you require a fixed installation, select a pump on a reservoir and mount one per unit of plant. Alternatively distribute the flow between a number of items of plant using a multi way valve. Fixed reservoirs can range from our miniature 100cc unit up to 50 litres.

Alternatively, use a portable reservoir and carry or wheel the pump to one of a number of installations. A hose and coupling on the portable pump can be snapped on to individual items of plant. Portable reservoirs can be supplied as 5, 10 or 20 litre portables carry-round, 10, 20 or 50 litre two wheel trolley units or a 50 litre 4 wheel turntable trolley unit.

If you have a large volume at low pressure for transfer or charging, use a large displacement pump such as our MW-3-49 49cc or MW-3-100 100cc hand pumps. These can be mounted on portable reservoirs within the MP range or fixed reservoirs within the MW range. The MW-3 or MP-3 pumps are 316 stainless and bronze with only small amounts of stainless 302/303/304/420/431. An option for 100% external parts in 316 stainless and bronze is available. Alternatively, we offer a MP-A and MW-A series which use an anodised alloy body but the same hard chrome plated piston rod running in a 316 stainless liner.

All our MW series pumps used in our Charging, Filling and Lube Pumps feature high quality Micropac engineering proven over 35 years. Configure the pump exactly as you require it for your application, with optional release valve, relief valve or pressure gauge. A hard chrome plated 316 stainless piston rod and 316 stainless pump liner provides very low corrosion. Units are fully serviceable.

Hose storage is achieved on the two and four wheel trolley units by means of neat brackets.

The Micropac DUO two wheel trolley unit adds an air driven pump for deskilled filling, retaining the hand pump for final top up or operation when there is no air.

Whether units are used for lubrication, filling or charging, we can supply pumps with hoses and specialist quick disconnects. Contact us to discuss your requirement.

For very specialist applications such as API and Pressurised Sealing Systems, we have an expert distributor who can provide specialist solutions using Micropac equipment. This sector is a major user of our pumps. Contact us.

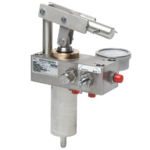

For modest system volumes, our MPF filler, lubrication and charge unit offers small space envelope that can be integrated into an item of plant. The swivel operating handle can be parked when not in use and positioned for ease of operation. There is a handle locking option to prevent unauthorised operation. The MPF units are available with a 316 stainless or anodised alloy body, small fixed reservoirs starting at a 100cc clear unit and are fitted with a pressure relief valve but no release valve. Inlet and outlet check valves are soft seat and poppet types and the unit is easily serviced. Other reservoirs are available. Contact the factory to discuss our MPF units and your application.

Micropac pumps are configured exactly as you require them for your application.

Contact us about a custom unit or to discuss your charging and filling application.