Corrosion is a very serious issue.

External environmental corrosion may mean that the first time a pump is used after a long period of inactivity, it has seized up or fails. Internal corrosion from stagnant or aggressive fluid may cause failure or spread contamination throughout a hydraulic system. Designers of high integrity systems where failure is very serious will worry about galvanic corrosion between different materials within the wetted parts even at a distance apart, particularly on water based fluids. It is always essential to differentiate between external parts and wetted parts, as each have different issues. When talking wetted parts, it is important to know the hydraulic fluid and the other components in the system.

Micropac hydraulic hand pumps offer solutions on a number of levels of corrosion resistance.

Our inexpensive but high quality MW-A hand pump still uses a hard-chromed 316 stainless steel piston rod, our unique 316 stainless barrel and stainless steel pivot pins. This is a lightweight hand pump unit with good corrosion resistance.

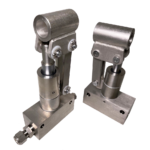

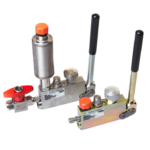

Our highly regarded MW-3 hand pumps use 316 stainless steel and bronze and can be upgraded to offshore trim for enhanced external corrosion. That upgrades all external materials to 316 stainless and Bronze CW307G.

Our large displacement MB Drum pump uses all 316 stainless steel and polymer wetted parts, as does our MU hand pump for unparalleled corrosion resistance.

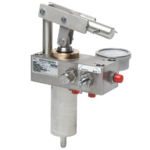

Our PPS 316 stainless System Builder range offer 100% 316 stainless for designers and specifiers of 316 stainless system, such as control systems or nuclear installations. This type of pump would be piped into a complex, high integrity systems using Swagelok double ferrule stainless steel fittings or similar.

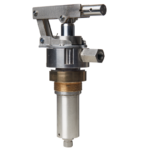

Our MT-6 Cartridge hand pumps are 316 stainless steel variants for very compact and cost effective corrosion resistant manual hydraulic units.

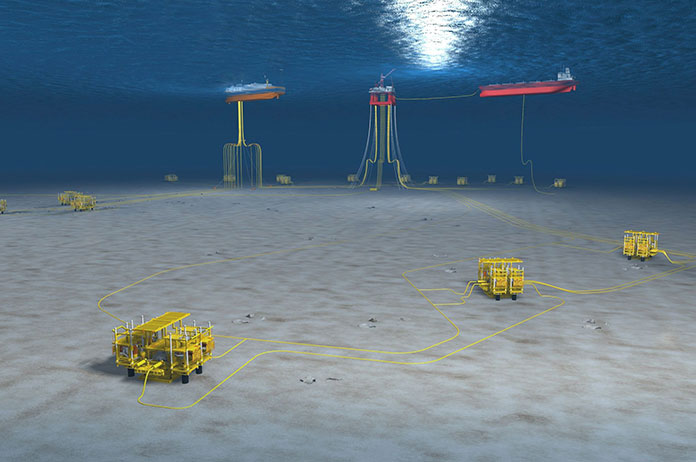

For high external corrosion resistance and an “industry standard” footprint, our MG series uses our proven 316 stainless/1.4404 hand pump on a 316 stainless reservoir. Some of these units will retrofit in place of other manufacturers’ alloy and carbon steel units. An additional reservoir return or equaliser port simplifies installation. This equipment is used on subsea applications such as ESD systems and diving bell doors where alloy or carbon steel are unsuitable for safety and dependability.

Finally, Micropac hydraulic pumps do have the flexibility to offer hybrid designs where a particular area needs very high corrosion resistance and elsewhere can be good resistance. For example, on a wind turbine hydraulic system where cost is an issue over large numbers of units, a customer might specify a 316 stainless hard chromed piston rod, a 303 stainless barrel and hard anodised handle mechanism. For them, the previous experience of a carbon steel piston rod seizing up in a marine environment has been unacceptable. We have offered a very cost effective solution to a particular need on marine wind turbine hydraulics in the Renewables industry.

Contact us to discuss low corrosion Micropac hand pumps for any application and extreme environment hydraulics.