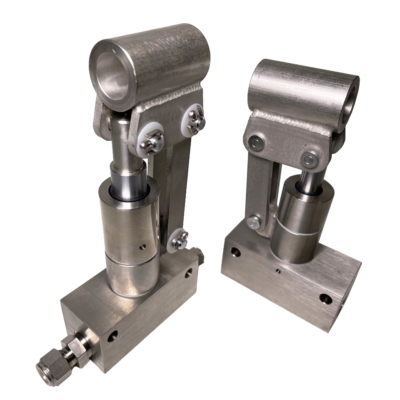

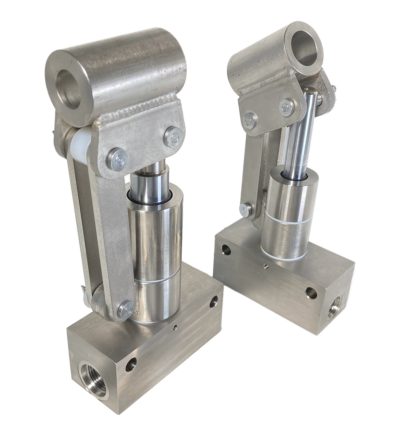

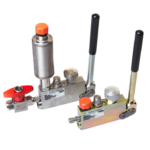

Durable hydraulic hand pumps for System Builders, in 100% 316 stainless steel and inert polymer for demanding applications where galvanic corrosion is unacceptable.

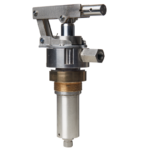

Typical applications include control systems, actuation, pressurising accumulators, manual over rides and standby hydraulics. Industries include nuclear, oil & gas, process and wind power. The unit is very compact and is fitted with a detachable 316 stainless steel handle and 360 degree swivel mechanism for maximum flexibility for the operator. Displacements up to 11 cc per stroke single acting and pressures up to 400 bar are available in three models. True multi fluid capability. Easy supply and fitting of alternative seals for specialist fluids like Skydrol phosphate ester aerospace oil. The standard unit is compatible with oil, water or glycols. Low temperature seals down to -50 degrees C are an easy option in response to customer needs worldwide.

If you need to know more about hydraulic hand pump basics, watch our video on “single acting and double acting hand pumps. What’s the difference?”

Why buy a Micropac PPS 316 Stainless Steel and Polymer Hand Pump?

- Suitable for extreme applications – corrosion resistant.

- Single grade of stainless for control of galvanic corrosion.

- Simple connection using “Swagelok” catalogue double ferrule fittings or threaded adaptors.

- Three models for optimum application, covering 1 bar to 400 bar range.

- Universal fluid compatibility by design – oil, water, glycols, ‘skydrol’ and more.

- Very easy seal upgrade to “viton” fluorocarbon, epdm or -50 degree C low temperature seals.

- Compact with 360 degree handle swivel for ease of operation.

- Only EU or US stainless.

- Proven Micropac products used world wide for over 40 years.

Description

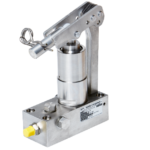

A range of rugged Micropac pumps designed to provide high integrity units for system builders, designers and specifiers of 316 stainless steel systems. The PPS unit is a very compact component hand pump with inlet and outlet check valves. It is a single acting pump and operates on the down stroke. A hold/release valve, relief valve or directional control valve would be piped in elsewhere in the system from discrete components. In manufacturing the unit from 100% 316 stainless steel and inert polymer, the risk of galvanic corrosion is reduced. Certain industries will not accept a mix of stainless grades and other metals especially when running on water or glycols. Galvanic corrosion can cause a component to fail or seize up. For many designers and specifiers, total integrity of material is essential, for example the nuclear or offshore industries. We offer three models which can be piped into a system using “Swagelok” catalogue double ferrule fittings or we can supply a range of adaptors to NPT female, JIC male or BSP male/female. What’s the benefit of Swagelok, Parker A-LOK and double ferrule compression fittings for high integrity 316 hydraulic systems? Read our take. A wide range of connections are possible so there is no reason to have to use bulky or leak-prone multiple adaptors. The pump has a small space envelope and the 360 degree swivel on the handle mechanism allows great flexibility on how an operator uses the unit. In summary, the Micropac PPS Hand Pump series offers a wide range of options to meet any customer requirement. The unit also offers excellent value for money. Service kits are readily available from us, the manufacturer. We have over four decades of experience in manufacturing our Micropac stainless steel hand pumps.

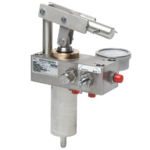

The Micropac PPS unit is purely a very compact component hand pump with inlet and outlet check valves in 100% 316 stainless and polymer. If you require a unit with integral hold/release valve, relief valve, directional control valve or reservoir, look at the MW-3 series units. These are largely 316 stainless but with small amounts of stainless 302/303/304/420/431 plus bronze CW307G. These are widely used on stainless steel systems throughout the world.

Trade marks Swagelok and Parker are acknowledged.

Technical Specifications

| Pressure: | 400 bar, 190 bar and 125 bar |

| Stroke volume: | 4.3cc, 8cc and 11cc |

| Materials: | 316 stainless steel and polymer |

| Seal options: | Nitrile & PU, optional ‘Viton’ or EPDM for “Skydrol” |

| Fluid options: | Mineral oil, water, glycols, ‘skydrol’, multiple fluids |

| Options available: | Low temperature seals to -50 degrees C |