Hydrostatic Testing- Proof, Burst or Cycling?

Hydrostatic testing is the process of pressure testing with a liquid, most commonly water, to verify the integrity of the system. In design, manufacture and throughout the service life of any pressurised product or system, hydrostatic testing plays an important role in differing ways. Here, we discuss the differences in hydrostatic test between proof testing, burst testing and cycle testing.

Any pressurised system is a safety issue and poses a hazard and an associated risk of incident and injury. In hydraulic systems, the risk is reduced because the media is incompressible and therefore any stored energy released through a burst quickly dissipates. In pressurised gas systems, the potential for injury is greatly increased due to the media being compressible, and therefore the stored energy takes much longer to dissipate. Think how long air takes to release through a tyre valve at 3 bar then consider that industrial gases, for example, are typically stored at 300 bar. Apart from projectile injury, asphyxiation and toxicity are also a major hazard in the event of any leakage.

In terms of product design and manufacture, the Pressure Equipment Directive (PED) deems that any system pressurised to greater than 1 bar (14.5psi) is within scope and must therefore satisfy design and testing requirements of the PED and any related Design Standards. The higher the pressure and volume, the stricter the regime for ensuring safety of the design and production. Once in service, the Pressure System Safety Regulations take over and cover the inspection and maintenance of plant and equipment pressurised with steam, gases or liquid/ vapour mixes, but not hydraulic systems. Here, organisations must produce a written scheme of examination of all pressurised systems and a schedule of maintenance and inspection according to the requirements laid down.

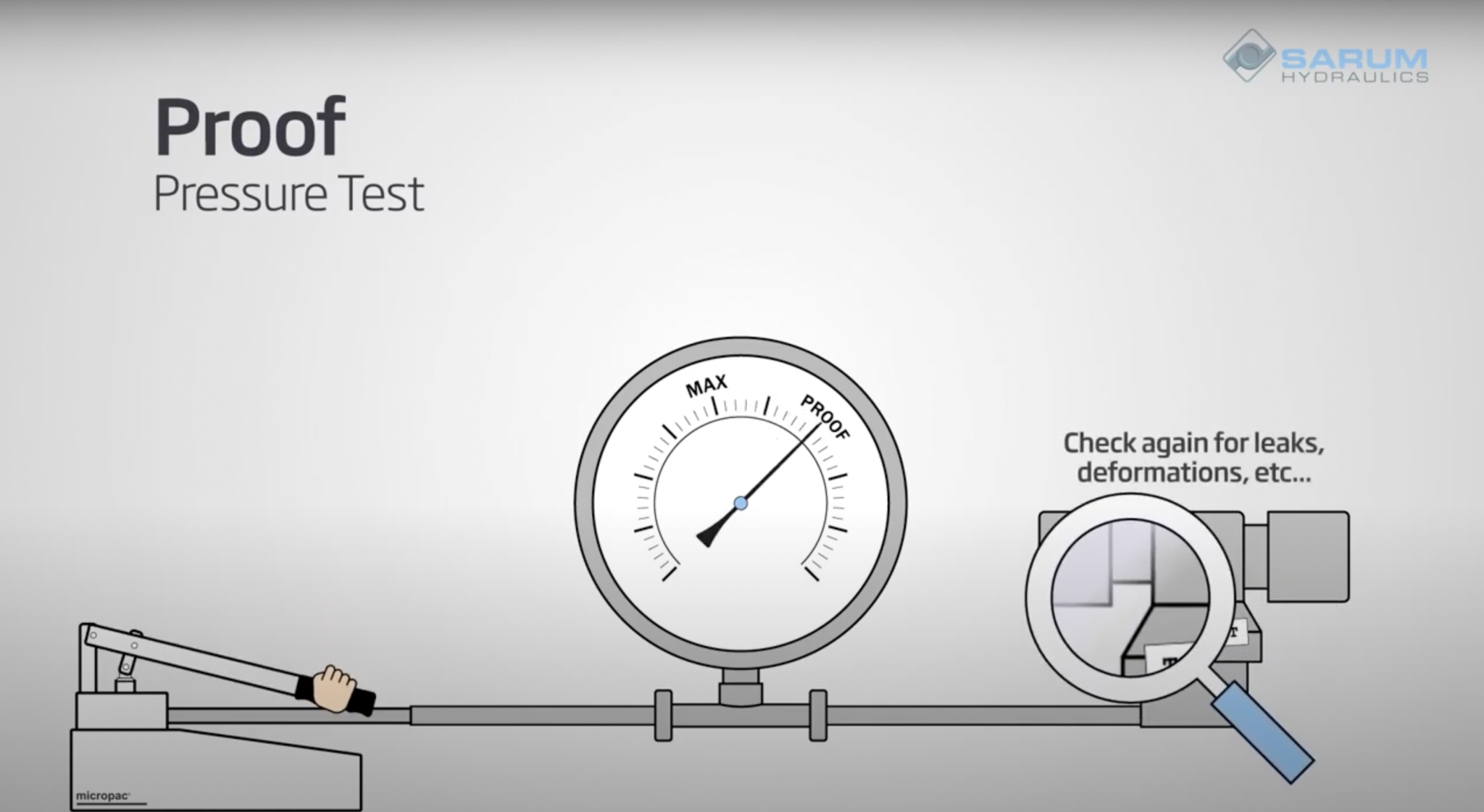

So starting with product design, whilst CAD 3D modelling and software to establish material isn’t over-stressed make for a good design on ‘paper’, the PED and associated Design Standards will invariably demand that the design is verified and that the product is proof tested and in some cases also burst tested. The proof test is defined as maximum working pressure multiplied by a pre-defined safety factor, most commonly 1.5. It is essential to carry out this testing hydrostatically for the reasons already outlined above. Using one of our Sarum Hydraulics MP or MD range hydraulic hand pumps with water and a pressure gauge is a simple and cost effective solution. You might specify a drag pointer on the pressure gauge as that can be really useful when conducting a burst test (as opposed to a simply hydrostatic proof test.)

The designer may also want to consider cycle testing to establish product life cycle or consider fatigue. Typically, the product is incorporated into a test rig and pressurised then depressurised for a predetermined number of cycles; if for example the product is a valve, then it may be operated each time to release the pressure. But the product could easily be a plastic bottle where the designer may be wanting to compare performance of a more eco-friendly material with a conventional polymer, in which case it would be pressurised and depressurised on a predefined test cycle to failure. Bespoke pressure test rigs of this type can be very expensive; here at Sarum Hydraulics we have developed an ‘off the shelf’ PTR programmable cycle pressure test rig which is low tech and relatively inexpensive. This has a maximum pressure capability of 290 bar (4200psi) and can operate up to 200,000 cycles. The computer programmer will catch the burst pressure if the unit under test fails, then shut down the system.

Thinking about production, hydrostatic testing plays an important role in proof testing in order to establish the integrity of the product assembly. Again, reducing risk by using hydrostatic testing in preference to pneumatic testing is an important consideration. Water is an ideal test fluid in many cases because it is easier to decontaminate the product after test. If production volumes are low, or if SPC (Statistical Process Control) is employed and volumes are manageable, using one of our Sarum Hydraulics MP or MD range hydraulic hand pumps with water and a pressure gauge is a cost effective solution. If volumes are higher, you could consider using our PTR programmable pressure test rig. With a purpose designed fixture and guarding to suit your requirements, the unit under test could be quickly fitted onto the rig which will then automatically conduct a single cycle proof test.

Hydrostatic proof testing also plays a critical role in pressurised installations anywhere, whether it be within buildings and factories, or on vehicles, ships and aircraft. The integrity of the system has to be established during the commissioning phase and Sarum Hydraulics hand pumps for water and oil enjoy widespread use worldwide for a multitude of proof test applications. Tasks range from commissioning of commercial heating systems through to verifying welded joints on nuclear installations. Professionals throughout the world use our equipment.

In terms of ongoing maintenance and repair, hydrostatic proof testing similarly plays an important role in ensuring the integrity of products and installations that a visual inspection might not otherwise establish. Commonly, Sarum Hydraulics hand pumps are used for such diverse applications as proof testing fire extinguishers and aircraft hydraulics ground support equipment.

Sarum Hydraulics have 35 years of experience in supplying hydraulic hand pumps for every sort of hydrostatic test. Whether it be one of our range of catalogue hand pumps and reservoirs for fixed and portable applications, or our programmable PTR cycle test unit, we offer a personalised service in matching our specialised product range to your exacting requirements. Call or email us today about your needs.

Watch our YouTube video which explains the terminology of testing.

Need more nuts and bolts help on your application? Other resources on our Sarum Hydraulics web site include how to Hydrostatic Test and a sample procedure, Sample of Risk Assessment for Pressure Testing and How to Create a Hydrostatic Pressure Test Certificate.

Look at our Solutions for Hydrostatic Pressure, Proof ,Burst and Fatigue testing on our website.

Leave A Comment