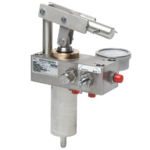

Micropac rugged and cost effective 316 stainless Subsea and Diving Bell Door hand pumps offer dependability and service life.

The Micropac MG handpump and reservoir provide a corrosion resistant kit for offshore environments. This variant on the MG pump provides an integral unit for subsea use and Diving Bell Door application. Our well proven MW-3 handpump is mounted on a stainless steel reservoir, which in turn has industry standard mounting centres for ease of retrofitting. The reservoir has four G1/2 ports in it, two behind the pump and one on each end. One port will be connected to a bladder or equaliser supplied by the customer. The reservoir is not a pressure vessel and must be compensated for a pressure of over 0.3 bar.

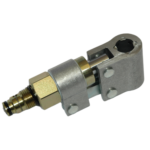

This unit has an integral reservoir. If you require a component hand pump or a pump with a different size of fixed reservoir, look at our MW-3 range. This can be supplied with 100% 316 stainless and bronze external parts, making it suitable for subsea,

Sarum Hydraulics has long experience with marine applications for hydraulics.

Why buy a Micropac MGS Subsea & Diving bell handpump?

- 316 stainless steel and naval bronze for very high corrosion resistance

- Industry standard footprint and mounting centres

- Compact and rugged design

- Choice of displacements and fluids on MW-3 stainless handpump

- Detachable handle minimises footprint

- Universal fluid compatibility by design- oil, water, glycols and more. Easy seal swap.

- Long service life and proven design for harsh environments

- Proven for subsea and Bell Door application

What is special about a submersible hand pump?

Micropac pumps have been used for decades in subsea applications. Again, application is everything.

Often, they are replacing a carbon steel hand pump. In reality “epoxy coating” of a carbon steel hand pump falls down where a carbon steel piston rod is left running in a steel bearing, pivot pins are still carbon steel and a needle valve spindle thread is steel in steel. There is no substitute for engineering these parts properly in subsea materials, although the argument of using carbon steel for a month or two until it seizes still seems to be tolerated in the industry.

The amount of fouling and corrosion will vary depending upon the location and depth. Often, equipment in a splash zone or only submerged some of the time will be most demanding on corrosion and pumps in shallow water most challenging on fouling. Some of our pumps are supplied with protective bellows over the piston rod to cut fouling but many customers don’t go down this route for various reasons.

Equipment deeper in the sea may be easier on corrosion if there is less oxygen, but other issues become important. Our reservoirs won’t be pressure vessels and will include a connection for a customer bladder type equalizer or accumulator to balance the pressure inside and outside the reservoir. These equalisers can themselves be expensive components. In reality, a diver won’t be able to generate massive hand loads, so we invariably specify smaller displacement pumps and lower handle loads. Also be aware that gloved hands will find it easier to operate quarter turn ball valve levers or larger handwheels rather than instrument knobs.

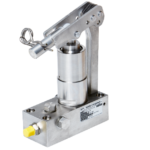

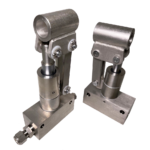

Our MGS Bell door and subsea pump is a basic submersible hand pump based on our 100% 316 stainless and bronze external wetted parts MG unit mounted on an integral 4 litre (2.5 litre in vertical mounting) reservoir. Extra reservoir bosses are fitted for easy connection of an equalizer and system components without the need for complex extra fittings.

Description

This corrosion resistant pump and reservoir has an industry standard footprint for easy retrofitting. The reservoir is mounted on M8 300mm X 121mm centres and constructed fully from 316 stainless steel to provide the highest level of corrosion resistance in an offshore environment.

The reservoir has FOUR G1/2 ports in it, two behind the pump and one on each end. Whether the unit is mounted horizontally or vertically, the designer or installer has a filler port, a drain port and connection for an equaliser without having the complication of extra fittings. Choose any MW-3 pump to fit on this reservoir, providing a full range of displacements and fluid compatibilities. For the full specification of your MW-3 pump, see our product page or contact us on 01722 328388 to discuss your requirement with an application engineer.

Technical Specifications

| Reservoir Volume: | 4L horizontal mount, 2.5 L vertical mount |

| Mounting Centres: | M8 121mm x 300mm centres |

| Mass: | 5kg including pump |

| Materials: | Reservoir: 316 stainless steel and naval bronze |

| Pressure: | MW-3 handpump: 100 – 700 bar |

| Stroke volume: | MW-3 handpump: 7 – 50cc |

| Seal options: | MW-3 handpump: Nitrile, Viton, EPDM |

| Fluid options: | MW-3 handpump: Mineral oil, water, glycols, multiple fluids |

| Applications: | Long life dispensing from fixed reservoir in offshore environments |