Micropac rugged and cost effective 316 stainless yacht and marine panel hand pumps for your cockpit or exterior system.

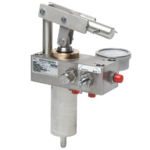

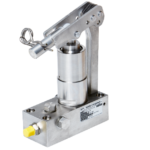

The Micropac MPP panel pump is a compact and lightweight corrosion resistant pump module for mounting behind a panel, for example on a yacht or in a control system. You can also mount it through a bulkhead or reservoir. We provide the pump module. You mount it on your panel, bulkhead or reservoir. The “business” side of the pump that faces the weather is sealed from the connections the other side of the panel. You build your panel to suit the application. Externally, a handle shaft is fitted with a handle to operate this double acting hand pump which pumps in both directions. There is also a hold/release valve knob for releasing system pressure. The pump operates to 300bar on mineral oil. Single and dual speed versions are offered, the dual speed unit providing a high displacement up to changeover pressure at which point the unit automatically switches to smaller displacement up to 300bar. A relief valve is fitted to limit the pressure.

Who would use the MPP panel mount pump unit?

Designers and specifiers who need to provide a compact, cost effective and corrosion resistant hydraulic handpump panel would integrate our MPP pump unit as a well-engineered solution. With a 100% 316 stainless steel handle shaft, handle and release valve facing the weather and low corrosion hard anodized alloy, bronze, and stainless steel behind the customer panel, you have the basis of a rugged and compact power unit.

Pipework is bulky, expensive, and unsightly if in view. For years, our MW handpump customers have used our pumps on the lid of a 316 stainless reservoir and ordered a base outlet so that all connections and pipework are hidden inside the reservoir. They fit additional manifolds, directional valves and control knobs or levers on the lid, connecting them inside the tank. These units are so neat and vulnerable pipework and hoses are hidden. Your pressure connection can even be a boss or bulkhead connector in the tank lid. The MPP provides an even neater and smaller solution for panel or system builders.

People who need a manual hydraulic panel for a yacht or marine installation already have an oil feed hose or pipe so don’t have an oil reservoir and horizontal lid for easy mounting. Yacht panels are invariably for vertical mounting in a cockpit. The neat solution is to use our MPP panel pump mounted behind your panel. You would laser or water jet cut then engrave a panel to your requirement and whatever aperture is available. Our pump module provides a handle shaft, handle, and release valve in 100% 316 stainless plus a hidden very low corrosion pump module with an adjustable relief valve and connections for pressure, tank feed and a pressure gauge feed. You mount any other hydraulic components that you need behind the panel, fitting a panel mount pressure gauge and any shut off or directional/distribution valves as panel mount parts as well. You can also mount the pump on a reservoir panel to achieve the same function.

What functions can a panel pump module based on the MPP offer?

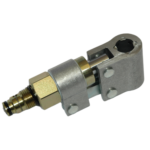

The pump has connections for the reservoir, pressure system and a pressure gauge. In the simplest form, the pump could power a single acting cylinder or actuator with the relief valve setting the maximum pressure and there being no pressure gauge to indicate load or pressure. The panel unit can be considerably more sophisticated, to suit the application. The customer might mount a panel mount pressure gauge in the panel and connect it to the MPP pump. Where multiple single acting cylinders or actuators such as a yacht backstay tensioner or boom range are required, a three-port valve or even five-port valve are mounted on the customer panel, with the feed connected to the pump. The five-port valve has one inlet and up to four outlets. Double acting actuators would require a four-way, two position valve mounted on the panel and connected to the pump. Designers will normally be cautious of making a manual system too complicated with an excessive number of levers and valves. Considerable care is needed, as an engraved instruction plate with a complicated operating sequence isn’t a good idea if safety is involved.

Could I use a panel pump from one of the large yacht equipment manufacturers?

Yes, you could, particularly if you wish to maintain the same brand throughout. Hydraulically, there is no problem in mixing components provided you know exactly the specification on the actuator and what functionality is required. Use of the MPP unit can provide a cost-effective panel power unit, a panel engraved and branded to your own style and can provide the exact functionality that you require. Sarum Hydraulics provide the MPP pump, and you design your system using our pump. We don’t supply the panel or additional components.

Could I use an MW-3, MD-6 or the small PPS system builder pump instead?

You could, but the panel-based pump unit is just so neat. Only the handle shaft and release valve are visible with all other components sealed behind and out of view plus tucked away from the weather. Once you move to a conventional hydraulic system, you have the complexity of components piped or hosed together plus the difficulty in changing the handle mechanism on the pump to look slick. Note that the yacht industry commonly uses commercial hydraulics for items such as drop keels and mounts power packs down below away from the arduous environment. The panel pump unit based on the MPP invariably needs to be mounted in the weather and is used outside.

Should I use a single or dual speed pump?

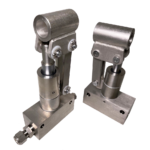

The mounting interface is identical and only the dual-speed pump body is slightly larger. Use a single speed if this provides the performance your customer needs. That pump will be cheaper. The dual speed version of the MPP has a larger displacement to a changeover pressure than moves automatically to a high-pressure stage. This type of pump will provide faster operation, which might well be an issue if the user is racing or under time pressure.

The MPP panel pump has wider applications than just the yacht industry. It was designed specifically for this type of hydraulic panel pump module where trying to fit a conventional component hand pump is impossible. Production of your own custom panel pump module either for one offs or numbers is highly cost effective.

Contact us to discuss your requirements.

Technical Specifications

| Pressure: | 1 – 300 bar |

| Stroke volume: | 5.8cc / Double stroke to 300bar on Single Speed

17.4cc / Double stroke to 100bar, then 5.8cc / Double stroke to 300bar on Dual speed |

| Materials: | Anodised aluminium, 316 stainless steel and bronze |

| Seal options: | Nitrile, optional ‘Viton’ or EPDM for “Skydrol” |

| Fluid options: | Mineral oil, consult factory for options |

| Options available: | Directional valves, pressure gauges, consult factory for special requirements |