Just a quick online search for manual two speed hydraulic hand pumps (or “two stage hand pumps)will show up a multitude of different options currently on the market. Many of these workhorses have been around for more than 50 years. There are 700 bar oil hydraulic pumps by the dozen from all the big players. Search for units that run to 700 or even 1000 bar suitable for hydrostatic pressure testing on multiple fluids including water, glycols or “skydrol” and you are in more specialist territory. Building units to form “pressure test rigs” or “hydrostatic test sets” and customised to do a specific job are yet more specialist.

We published a great white paper on selecting a two speed pump People have found this incredibly helpful in explaining two speed pump basics and helping them to make a choice. We talk about 700 bar oil hand hydraulic pumps like the Enerpac P141, which is great kit for the right application. We examine big alloy square workhorse pumps like the Tangye Hydrapak, the Hi-Force HMP, the Hi-Force MHX or the Enerpac MP series. We have used them over the years.

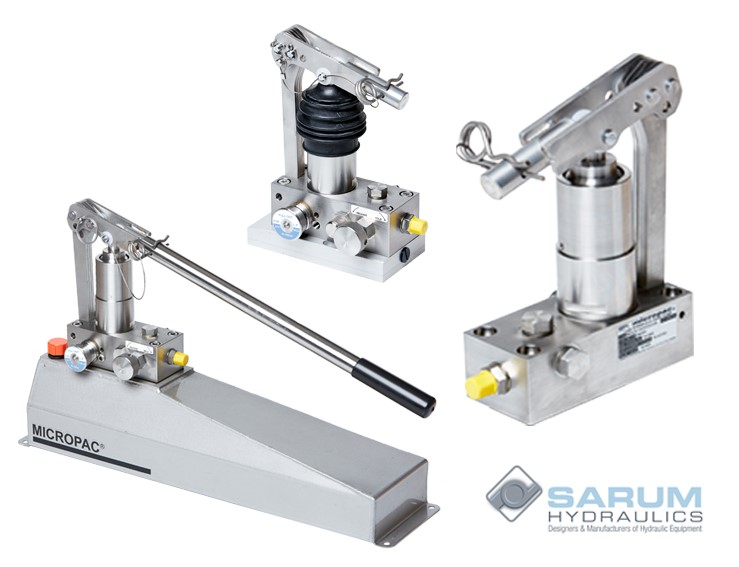

Indeed, these 89mm alloy body pumps have a strong following in the marketplace and loyalty with users. Having looked at various models we homed in on how we would improve the concept yet keep 100% retrofit ability. Our big things were an anodised corrosion resistant body in 6082T6 alloy, fully replaceable seats from a low cost comprehensive service kit, the ability to swap easily to different seal compounds such as fluorocarbon (“viton” or peroxide cured EPDM for “skydrol” and a good value 100% British product. That’s what our own Sarum Hydraulics Micropac PSP series pump delivers in its six models running all the way to 1000 bar. As always, Trademarks are acknowledged.

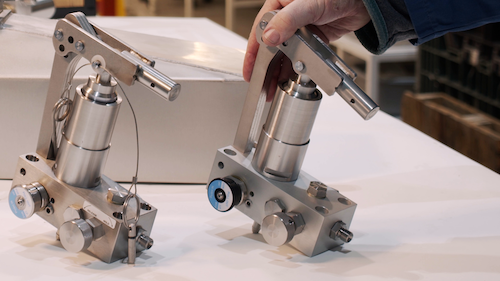

Despite the following for the 89mm square industry standard pump, we could see an opportunity for a more compact unit in stainless steel. That was our MD series pump.

So, what did our Sarum Hydraulics designer build into the Micropac MD series two speed manual hydraulic hand pump that is so special? After 35 years, we think we have quite a lot of experience in what makes a good two speed pump. Let’s dig deeper into our big features.

Compact Size and ergonomics for the user.

Moving to a much smaller and more ergonomic space envelope. Love them or hate them, big old two speeders manufactured with a 90mm square of alloy and a steel handle shaft sticking out of the side just seemed outdated. We think the handle on the centre line of the pump is easier.

Easy multi fluid compatibility.

If you are running on mineral oil, life is easy. If you move to synthetic oils like water glycols, PAG’s or skydrol you don’t want lurking corrosion problems. Internals must be up to the job and you do need to know that a seal kit is cheap and ex stock. Moulded seals can be a disaster when it comes to special seal compounds. If you need a two speeder with fluorosilicone seals, we will supply a cost effective unit on short lead time. You also want to be able to run on water and kerosene/jet fuel with no wobbles on poor check valve performance when using low viscosity fluids.

Rugged 316 Stainless Steel option.

People throughout the world use Micropac 316 stainless pumps every day. If you really need 316 stainless you can specify it.

Our anodised alloy and stainless unit is still properly engineered.

If your application allows you to use stainless and anodised alloy, then that will cut cost. We still run a hard chromed piston rod in a 316 stainless liner. We have never cut corners on our MW series and the same DNA is in the MD series two speeder. Forget 416 or 431 stainless piston rods. Our MD series customers expect 316 stainless rods.

No-nonsense manual change over.

We aren’t fans of automatic changeover on 700 bar pressure test sets like our MD series. Our customers seem to agree. We have a no-nonsense button.

Durable externals for a long life in the shop or on the rig.

Plated steel or paint has its place. Our designer just went for a stainless mechanism that won’t corrode, seize up or get stripped of protection if a solvent is sprayed on it. It seems right to us on a professional tool.

Easy and cost effective reservoirs.

Just pick a fixed, portable or two wheel trolley reservoir from the standard Micropac range. Anodised alloy or 316 stainless. Volumes from 2.5 to 50 litres. If you need extra bosses, level indicator or a label bracket, that’s something we can do.

Cost effective custom pressure test rigs and hydrostatic test sets.

After 35 years, we know our special hydraulic adaptors, couplings and hoses. Need a special gauge or modified reservoir? Talk to us.

Offer a retrofit option for legacy reservoirs and installations.

Users can bolt our MD series two speeder onto legacy 90mm square unit reservoirs. Our adaptor plate has a built-in strainer element and a durable metal, not pvc dip tube.

Simplicity and value.

We have always offered serviceable kit that is simple to dismantle and repair. Micropac pumps have always offered great value.

Ask the experts in manual hydraulics.

After 35 years, we are the experts on manual hydraulics. Contact us if you need any help in selecting a two speed unit for your application.

The end product. Our MD series hand pumps available as a bare pump, on reservoirs or for retrofit onto legacy reservoirs.

Related Links

Our white paper on the how to select a Two Speed Pump. Become an expert.

Product details on our web site for our MD series two speed pump.

Leave A Comment