SARUM HYDRAULICS LIMITED

Application notes.

Two speed hand pump. How do I select a two speed hydraulic hand pump?

When do you need a two speed hydraulic hand pump? What are the basics and how do I not get caught out with the wrong kit?

Basics.

Hydraulic hand pumps: The Basics

A hydraulic hand pump is a great way of getting a lot of jobs done. Filling, actuation, pressure testing, hydrotest and lots of other tasks. No air or electricity is needed. You pump a handle or pedal and can generate a pressure in a volume of oil at so much displacement or volume per stroke. If you don’t need to generate much pressure, the load will be low.

Let’s just clarify single acting, double acting, two speed, dual speed and two stage. If you are just generating pressure on the “down” stroke and sucking in on the “up” stroke as you pump the handle, this is termed “single acting”. Why not generate pressure on the “up” and the “down” stroke? Doesn’t this give you something for nothing? Yes, we think so at Sarum Hydraulics and our MW series pumps are all single speed, double acting, pumping on the “up” and the “down” strokes. The double acting pump is more complicated to manufacture, but in principle, these do get the job done quicker. Now move to a manual hydraulic hand pump that has two “pumps” or stages built into the one unit. A low pressure high displacement pump, a higher pressure low displacement pump and some means to change from one to the other. That is a two speed, dual speed or two stage hydraulic hand pump. Pretty well all two speed hand pumps are single acting, but don’t confuse that with two speed operation.

How do these Two Speed hand pumps work?

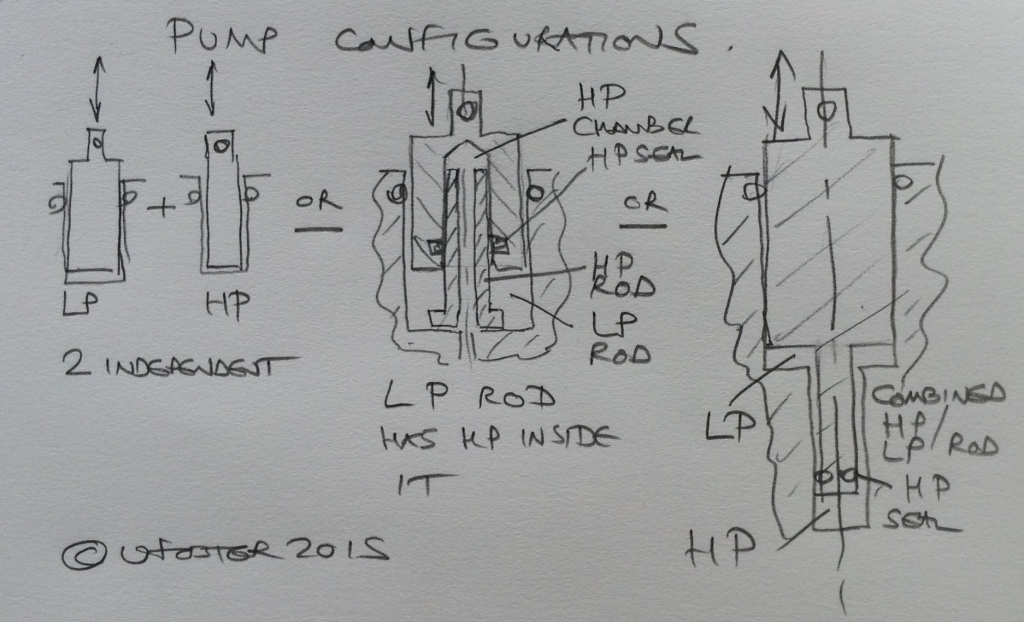

My diagrams are very simple sketches and treat the low pressure and high pressure stages as two separate pumps. In reality, there may be a single piston rod that has two diameters or a low pressure piston rod that has a female bore up the middle to take a sliding high pressure rod. The simplest two speed hand pump is of course just two independent pumps mounted up side by side and you swap the handle over. That option is not to be dismissed too quickly!

Diagram 1. Basic pump configurations. Two pumps, hollow LP rod or one piece stepped rod

Diagram 1. Basic pump configurations. Two pumps, hollow LP rod or one piece stepped rod

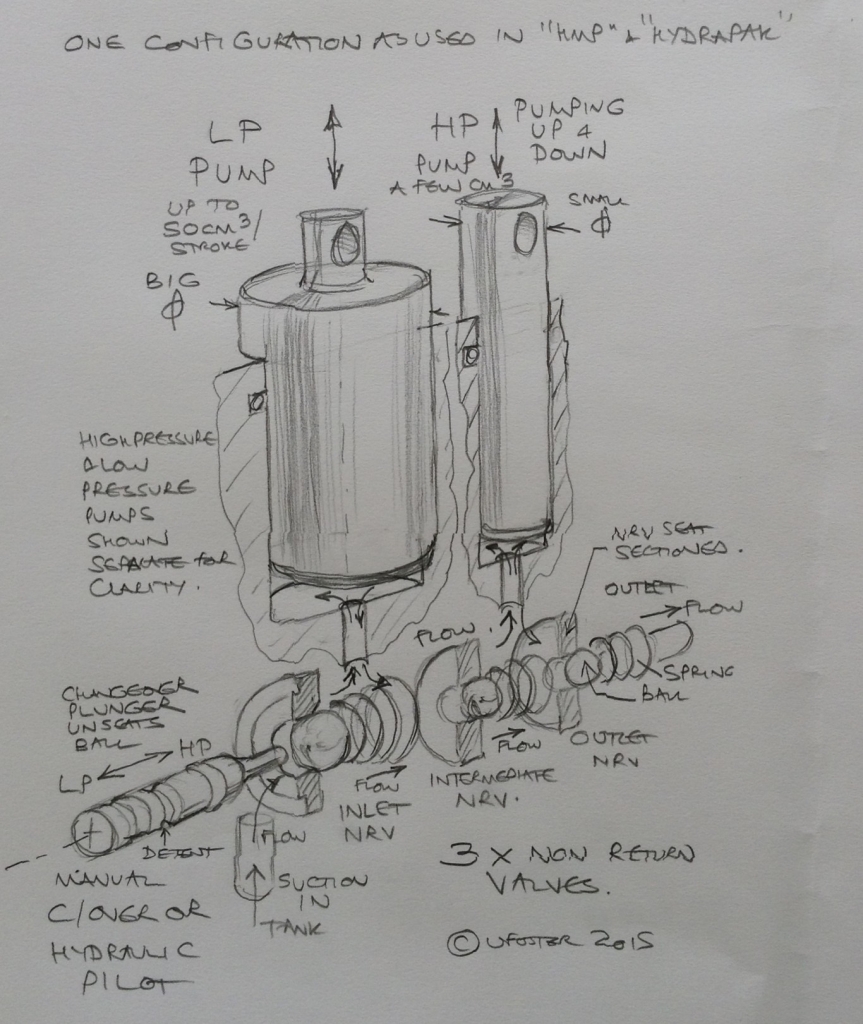

Diagram 2. Typical two speed hand pump configuration with its three check valves.

Diagram 2. Typical two speed hand pump configuration with its three check valves.

Diagram 1 shows in a simple sketch the low pressure and high pressure stages side by side, a low pressure rod with the high pressure running up inside it and finally a once piece HP/LP piston rod. Diagram 2 shows the relationship between the low pressure stage, high pressure stage and the three non return valves (“nrv’s”) that sit between them. I have sectioned the valve seats to make it clear how the Hydrapak, Hi-Force HMP, Hi-Force MHX, our Micropac PSP and our MD series pumps unseat the inlet non return valve ball when operating on the High pressure stage. See the paragraph on changeovers for a further explanation.

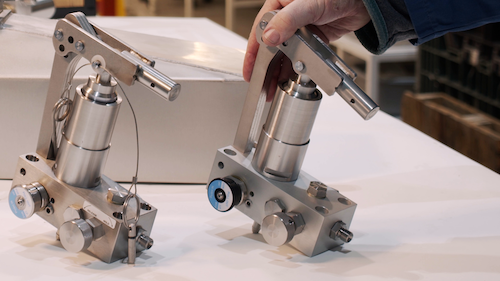

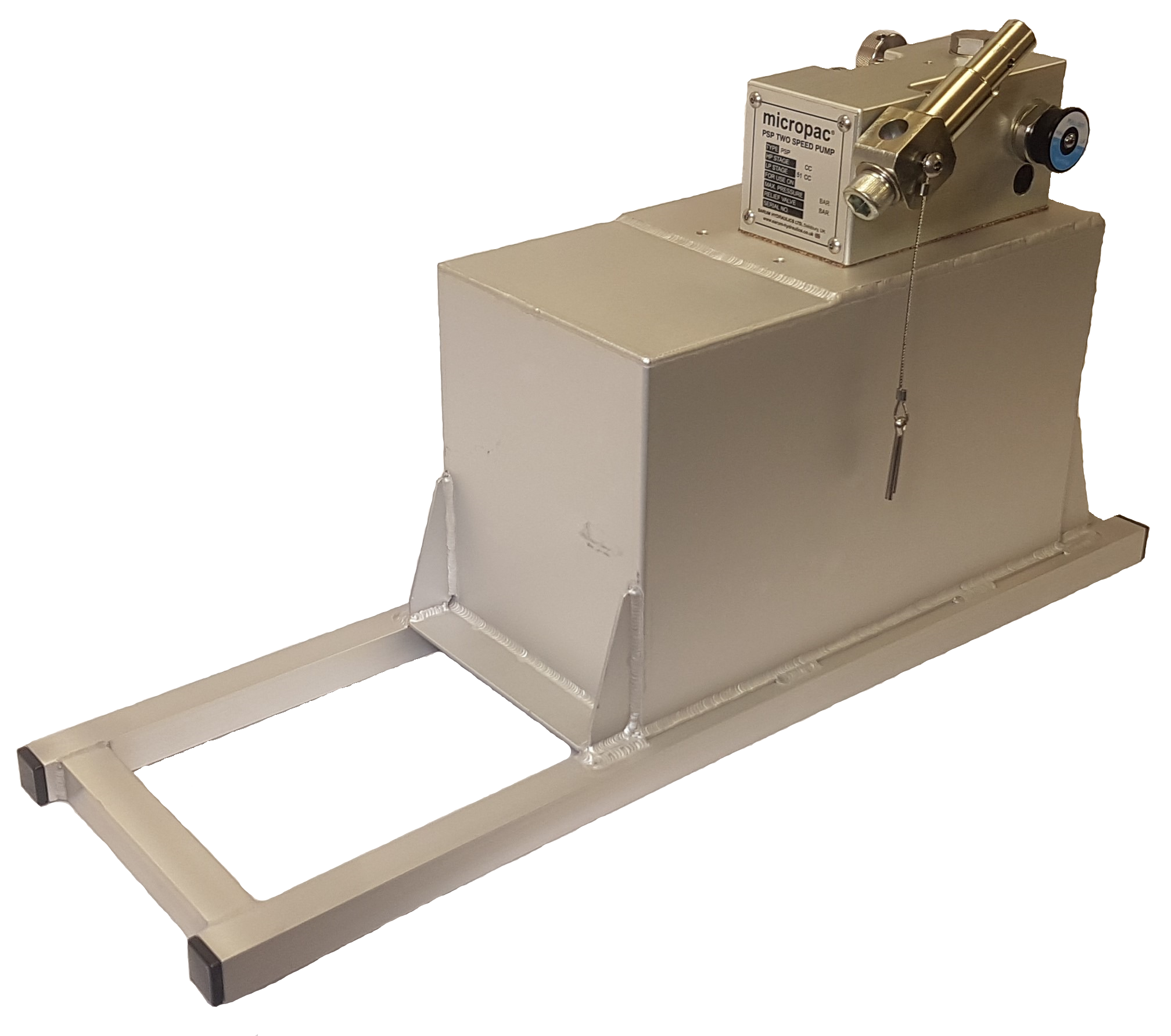

Image showing our two speed pressure test hand pump

Terminology. Are we all speaking the same language?

We have already explained about single and dual speed units. A single acting or double acting hand pump refers to whether the unit pumps on both strokes or one only BUT some people will refer to a double acting hand pump as one that has a four way directional control valve on it and will operate a double acting cylinder. Accordingly, the statement “you need a double acting hand pump” needs to be clarified every time. It is a real minefield.

The only other term to clarify is that a British non return valve is an American check valve. Even I like the term “check valve” as it is quick and easy.

Ergonomics and safety.

You may have the odd giant hulk working in the team but most people are going to be in the range of 5 percentile woman to 95 percentile man, so you design for what load they can exert in a safe manner for however long is comfortable. Never over-estimate the energy that a person can exert simply to meet a specification or fudge the figures. You have got to be realistic. Remember to keep in mind statutory requirements as to how much force a person can exert continuously.

Why use a two speed pump?

It would seem quite obvious that if you start a job and seem to be pumping a lot of strokes at low pressure before eventually pumping a few strokes at high pressure, you could reasonably say “surely I could have used a two speed hand pump and moved from a low pressure high displacement stage to a high pressure small displacement stage half way through the job and been finished in half the time?” That is the essence of a two speed hand pump.

Two speed hand pumps are tricky and not necessarily what they seem. On the face of it, the perfect hand pump is one that shifts a large volume at low pressure, and then automatically switches over to shifting a smaller volume at high pressure. Accordingly, the job gets done as quickly as possible with the operator exerting a steady amount of effort.

Basic arithmetic. Just check that a two speeder works on your job.

The first observation is that all dual speed hand pumps that we have ever come across in recent years are single acting, pumping on only the down stroke. We stand to be corrected on this (I might add that there was a Micropac unit that we produced up until 1986 that was double acting on the low pressure. I must admit it was mighty complicated, but nevertheless, it was an undeniably nice unit). If one quietly does the arithmetic on how many strokes the two speeder will take at low pressure, and then how many strokes the two speeder will take at high pressure, you may be surprised to find that a double acting single speed hand pump like our Micropac MW series which pumps on the up and down does the job quicker at half the price. We make two speeders and single speed, so we are happy to sell either! If your high pressure stage is less than say 400 bar, always do the arithmetic.

Subtle differences in two speeders. Manual versus auto. What about LP relief types on 700 bar pumps?

Just be aware that there are two speed and two speed pumps.

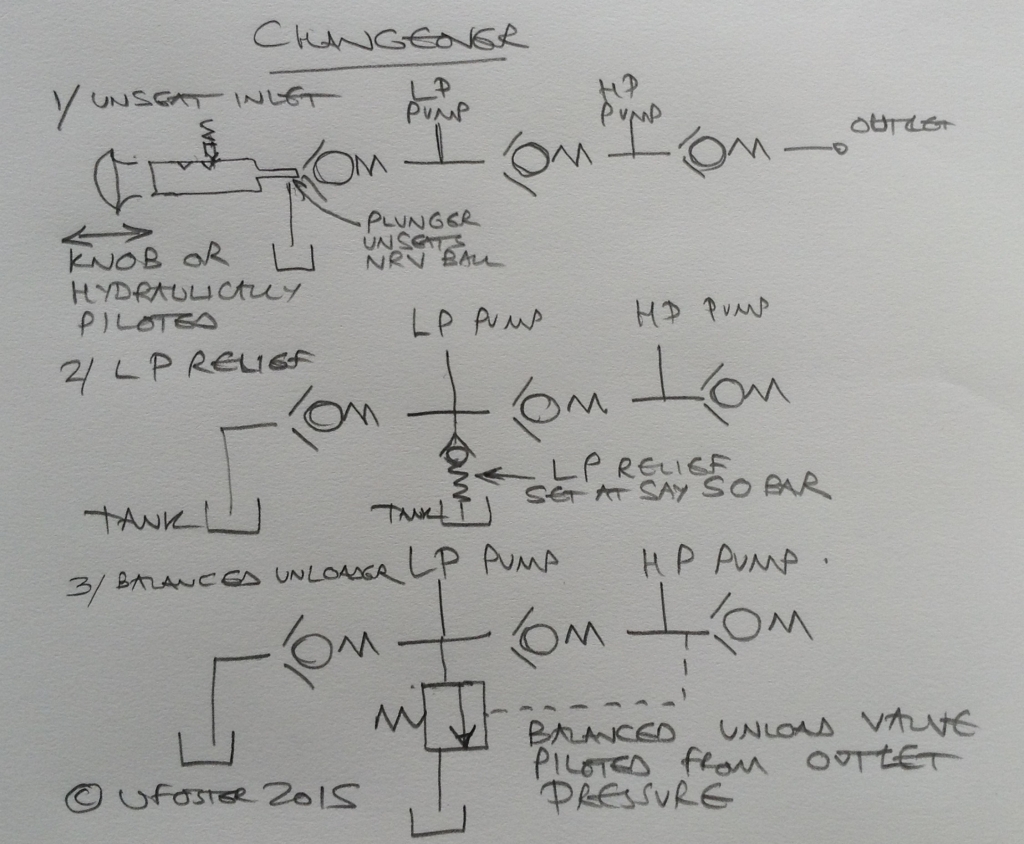

Diagram 3 attempts to show three permutations of changeover from low pressure to high pressure. I have described these as:

1.Unseating the inlet non return valve, either mechanically or hydraulically.

2.Using a low pressure relief valve on the LP stage

3.Using a balanced unload valve piloted from the pump outlet pressure.

Diagram 3. My take on three ways to unload the LP stage at changeover

Diagram 3. My take on three ways to unload the LP stage at changeover

Should we care how the manufacturer achieves the result? Probably not, except that the design has implications on how nice the unit is to use. There is also an issue of wasted energy. User preference also plays a part. As always, the list is not exhaustive, so feel free to suggest other ways of achieving changeover.

In theory, your low pressure pump needs to be unloaded with no wasted energy at the changeover pressure. The excellent PSP series two-speed hand pump (and our MD series) does this by manually unseating the inlet non return seat on the low pressure section, leaving the high pressure pump to run on up to the maximum pressure. This was the way the old Tangye Hydrapak (and more recent HMP and MHX pumps) did it and these units have proved amazing work horses. Diagram 2 shows this configuration. We are great fans. The plunger can be mechanically banged in to unseat the ball using a palm knob and a two position detent. To get back to low pressure, you just pull it out. Dead easy and mighty low tech.

Move to automatic changeover and life is more tricky. You could just use a miniature hydraulic cylinder loaded up against a spring to move the same plunger as our the widely used MHX/ HMP/Hydrapak/PSP design and mechanically unseat the non- return valve ball. That is quite reasonable, except that it isn’t balanced and can suddenly “let go.” More on this later. The nicest design (at least hydraulically) is a fairly sophisticated balanced spool valve, so as not to waste energy. Here you have a valve that holds pressure, is piloted off the pump outlet pressure and at say 50 bar will open and unload the low pressure stage back to tank. However you achieve a true automatic changeover with the low pressure stage not building pressure, there is an element of complexity. Just be aware that if you want a changeover that will last for years on water and is based on an alloy pump body, lots of people stick with a low tech manual changeover.

Don’t confuse automatic changeover to a high pressure stage with “two speed” operation used on a lot of 700 bar pumps by the industry (including Sarum Hydraulics on some OEM equipment) Here the arithmetic justifies a large volume low pressure pump with a low pressure relief valve which relieves at a low pressure, letting a high pressure stage carry on up to 700 bar. Yes, it wastes some energy but provides a rugged and low tech means of achieving two speed. It is a bit of a fudge but achieves the goal reliably.

Auto changeover doesn’t always feel as nice or safe as it should be.

This is where different designs do make a difference. If you are working on a flat solid surface and lifting a load, either a manual or automatic changeover two-speed hand pump will suffice. Just make sure that the operator knows that the manual changeover button needs to be pressed in to switch to move the high pressure. Even today, users continue to put a scaffolding pole on the handle to get the unit up to 700 bar! If pumps are being operated at great heights, having a smooth automatic changeover is vital. If it jolts, the operator can stumble. This can be easier said than done on any balanced unloader type changeover valve, although ironically the mainstream 700 bar “two speeder” with its inherent wasted energy is more controlled in this respect. We have used auto changeover units from other manufacturers which are really very “jolting” on the changeover, some quite unbelievably so for such expensive kit that has been manufactured for a very long time. One second you are on 300N of load and then suddenly it lets go as it changes over. This is definitely something to try before you buy, as this can prove rather uncomfortable. some are just horrible.

What does the pressure curve look like as you do the job?

If you are using a two speeder for pressure testing, the pressure profile over time is easy. You may use the high volume low pressure stage to pre-fill the unit and vent out the air at zero pressure. You then start to build the hydraulic pressure which creeps up to the changeover pressure, whether manual or automatic. The high pressure/low volume stage then takes you evenly up to maximum pressure. The pressure /time curve will just be a gentle curve.

Applications which cry out for two speed may not be so easy. A manual over- ride pump for a big actuator opening a ball valve will probably need to move to the high pressure stage to break the ball out of its seats and start it turning, drop back to low pressure, slowly build up pressure over a lot of strokes until it changes to high pressure again as it shuts. A manual changeover will work seamlessly provided the operator works the button. Just make sure an automatic changeover can cope with switching in and out as pressures rise and fall.

“All stainless” units.

Finally, just keep in mind that we have a long history of making 316 stainless units. The MD-6 two speed Micropac pump makes all the external parts in 316 stainless. Or buy the MD-A unit which uses an anodised alloy 6082T6 body and stainless external parts. For a long service life, we recommend a stainless steel piston rod and our Micropac poppet and soft seat check valves. If you are running on water or glycols, a stainless unit is a good investment. You will find that all our Micropac pumps offer great value compared with the “big players.” Hand pumps are Sarum Hydraulics’ life. Talk to us about your application on pumpsales@sarum-hydraulics.co.uk or 0044 1722 328388.

Our verdict. Three of the best Two Speed Hand Pumps and why we like them.

We have used a lot of two speed pumps over a long time. What do we like?

The images show an Enerpac P392 two speed hand pump, a Micropac PSP two speed hand pump and plus a Micropac MD-6 unit.

Enerpac P392

The Enerpac P 392 is a similar configuration to lots of “jacking and work holding” pumps. They are compact, include an oil reservoir and run to 700 bar using two speed operation. The pump produces 11cc per stroke single acting to 13 bar then 2.5cc to 700 bar. It is purely for use on mineral oil. Don’t even think of using it on water. Although the low pressure stage is way less than something like the HMP or MD, this type of pump is perfect for specific jobs. Whether you go for Enerpac, Hi-Force, SPX or all the other International players, they all do this type of unit. We like this unit as a general 700 bar workhorse around the shop and even bought one ourselves! They look good. It uses a plastic reservoir which will suit most users although a steel unit is still available for people who need something that is bullet-proof. Metallic parts are coated or covered with plastic mouldings which will probably enhance corrosion resistance but certainly isn’t anywhere near Micropac MW-3 resistance if you need long term durability outside or in challenging environments. Our first port of call on all things Enerpac is Shaw Hydraulics.

PSP Hand Pump fitted to 15 litre reservoir

Micropac PSP Two speed pump

Our PSP two speed pump. Provides 49cc per stroke up to 50 bar single acting on the low pressure stage then anything between 2 and 20cc per stroke single acting on the high pressure stage. Our own PSP pump have multi fluid service and is used for actuation and pressure testing. The low pressure stage is always 49cc per stroke but seven different high pressure options are available on the high pressure stage, running right up to 1000 bar. A very useful tool. The changeover is a rugged mechanical type. This unit uses the same envelope as the legendary Tangye Hydrapak as does the Hi Force HMP and MHX pump. Enerpac also make a multi-fluid pump that looks similar. These units have a massive following in the world. They are a fair old lump of alloy and in many respects, it is useful to hide the handle mechanism within the body, although this does add to the space envelope. We can imagine that the handle shaft on the side works brilliantly on high tonnage jacks where this pump is bolted on. The handle can be orientated in eight different positions for easy use. However, on portable test and filling units using the HMP, MHX, PSP or Hydrapak, we have always found the side handle shaft to be awkward compared with the Enerpac or Micropac handle arrangement. The other basic limitation is that the body is anodised alloy and a 316 stainless version is simply not available. Other than these two points, these are great unit that have a very strong base in the market and a massive installed user base. That won’t go away in a hurry.

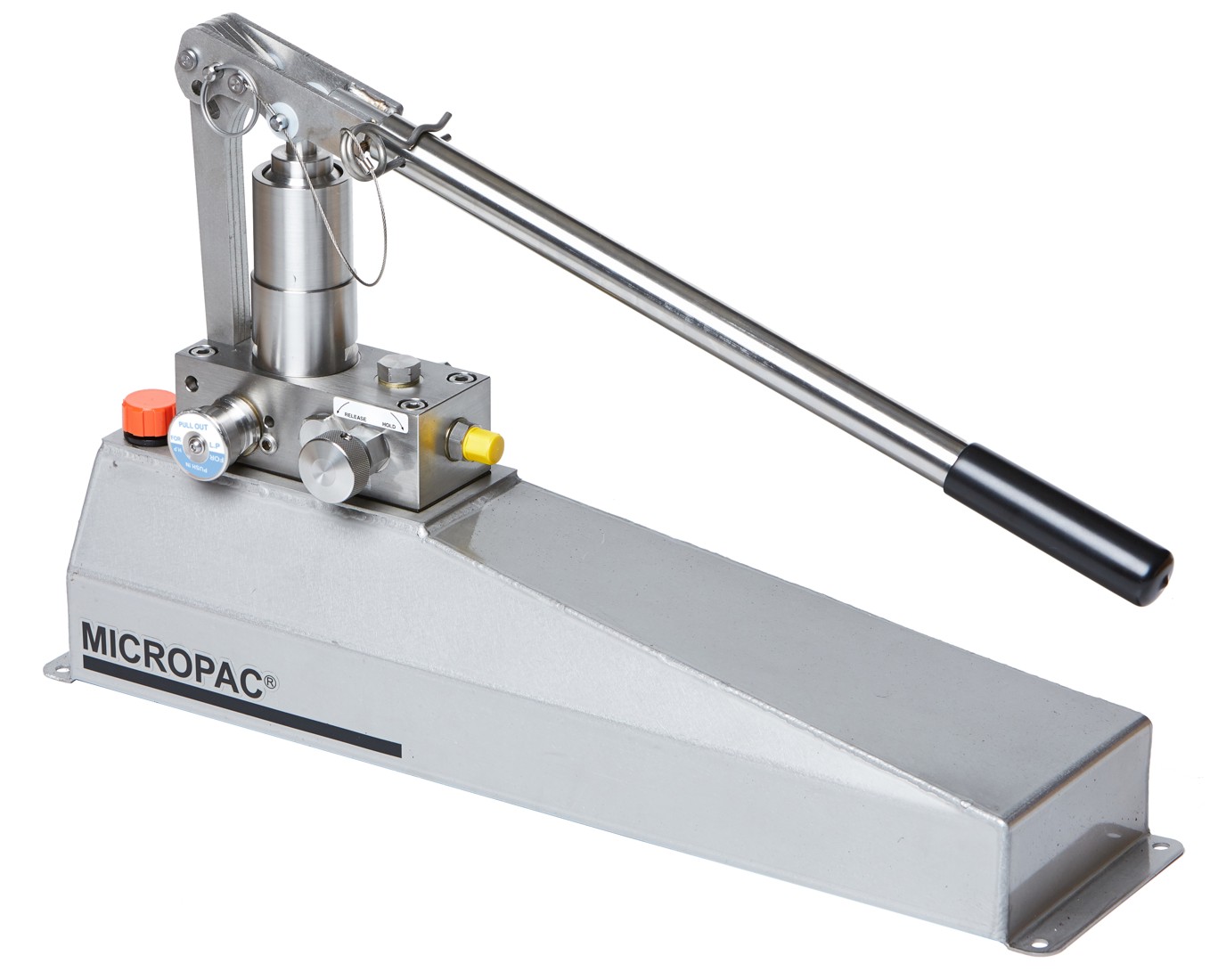

Micropac MD series two speed hydraulic hand pump

Micropac MD series Two Speed pump. Yes, we are fans. It is our unit. When we developed our own two speeder, we knew what made a good two speed pump. We wanted a Micropac quality stainless steel pump that provided great value compared with the big players. We went for:

Stainless 316 and anodised alloy options. No rust-prone carbon steel used in the unit.

Same compact foot print as our other Micropac pumps. A small space envelope yet rugged design.

The pump will fit on any of our MR reservoirs in stainless or alloy including these neat ERGO portable units. Our portable users value easy carrying, so the handle locks securely to form a neat and compact set.

Rugged and safe manual changeover.

Easy servicing with all seats replaceable easily and quickly. Low cost spares.

Learn more about our MD series two speed hydraulic hand pump from our designer.

Disclaimer: All Trademarks are acknowledged. The information and views expressed are personal from John Foster. Feel free to add to our knowledge database or correct me if there is something incorrect.

Copyright 2021 John Foster

Hello Mr. John Foster, thank you for sharing useful information with us. All hydraulic equipment are very useful with best features. Tangye pumps are now also emerging for best use.

Thank you for your comment, Hi-Press Hydraulics. Yes, we would go for a rugged manual changeover every time. The Hydrapak two speeder configuration is a rugged workhorse.

Hi Sir,

I need a hand pump at 25 bar max. with just one outlet for releasing the break from a hydraulic motor ( break cylinder is single acting )

No need for tank , I will connect through a hose

Regards

Eng. Amr

Good afternoon Eng.Amr, It sounds like you need a small pump but no reservoir. You will need to connect a tank supply hose onto a suitable connector in your system then have a second hose to snap onto the break cylinder circuit. I guess you need to release the pressure back to tank as well. Have you any more information on the circuit? To be honest, a small handpump on a skid is probably more expensive than a small handpump on a reservoir. 25 bar is very low pressure. We can do both. Talk further. E mail pumpsales@sarum-hydraulics.co.uk