Sarum Hydraulics are the experts on Miniature Hydraulic Hand Pumps.

Are miniature hydraulics the largest hydraulic application in the world?

Miniature hydraulic hand pumps are the ideal solution for difficult design challenges. Integrating a small pump and reservoir within a small space envelope and at low cost is an attractive alternative to piping up lots of larger hydraulic components, a mechanical solution like a screw jack or an electric actuator.

Worldwide, low tech manual or foot operated hydraulic pumps are probably the largest application for hydraulics if you count automotive braking or clutch hydraulics and in recent years, bicycle braking systems.

Who uses miniature hydraulics?

Our miniature hydraulic pumps have provided innovative products for our customers over many years. Key applications include:

- Seats for specialist off-road vehicles where a miniature pump and cylinder provides easy adjustment up and down.

- Manual braking on winches and vehicles has been another strong application.

- Emergency hydraulic power on systems for Public Service Vehicles (PSV’s) for vehicle tail lifts has been another big application.

- Manual over ride pumps to provide either back up power for actuators or the primary source of power for small actuators has also been a strong area of expertise.

- Lubrication and charging for mechanical sealing systems is also an application.

Very small integrated hydraulic pumps allow designers to use multiple units very close to the actuator or pressurised system rather than a single pump and pipework to feed multiple actuators or devices. This can be beneficial as it cuts complexity. Some very useful forces and strokes can be generated. One large Micropac OEM application uses an MC series pump connected to one of our 095 series miniature pull cylinders via a small bore Polyflex hose. The cylinder generates 6500N and a 75mm stroke, all from the sub miniature MC series pump.

What are the benefits of miniature hydraulics over electric actuation?

Although electric actuation has seen massive growth in the last decades, hydraulics still offers some unique control features. For example, on a vehicle seat, customers require the ability to drop the seat in a second or two by lifting a small lever. We are told that is very tricky for an electric actuator. Other users simply won’t entertain 100% reliance on battery electrics. In their hour of need, a battery could be flat. Hand hydraulics is dependable. Finally, in a world of very stringent safety requirements for powered actuation, a hand hydraulic system has big benefits. Stop pumping and the actuator no longer moves.

Materials are carbon steel or anodised alloy for mineral oil and stainless 316 for more demanding fluids or environments.

What products do we offer?

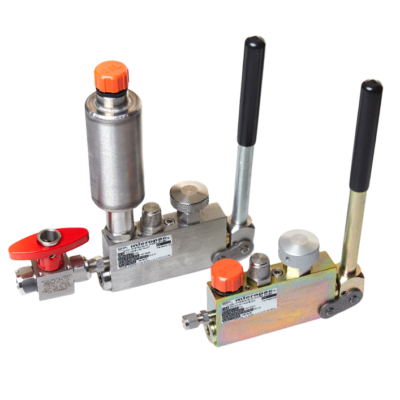

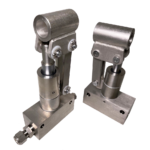

Look at our Micropac MC miniature hydraulic hand pump and reservoir. This unit is very small and manages to integrate a 400 bar hand pump for mineral oil, a release valve, a relief valve and an integrated 25cc reservoir machined into the body. Add a 175cc screw-on reservoir for more capacity. Plated carbon steel is the basic unit material. A 316 stainless option is available, as are 3 and 4 way valve options. The MC is used on mineral oil. Contact us to discuss your miniature hydraulic application for our MC unit.

Our Micropac single and dual speed MPM pump modules offer a unique OEM manual power solution. Pumps include a hold/release valve, a relief valve and a sealed reservoir in a bladder, allowing the pump to be used in any orientation and removing the need for a reservoir to breather or have a large air space. Usable volumes are 50cc on the single speed unit and 120cc on the dual speed pump. The standard 620 bar unit is fitted with a Minimess connector for easy spill-free connection and convenience. There is a 700 bar OEM version. These are units in aluminium alloy/carbon steel/stainless steel and are for use on mineral oil.

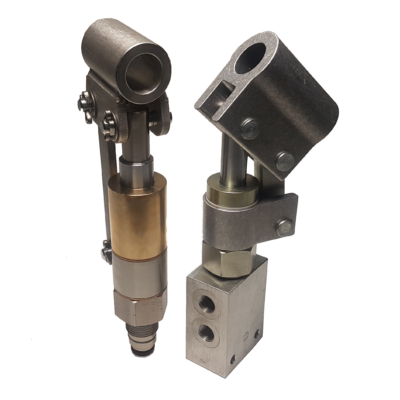

For small systems, our MPF filler, lubrication and charge unit offers a very neat package for installation on individual items of plant. The space envelope is very small, the operating handle is on a swivel for easy operation and neat parking out of the way when not in use. There is a handle locking option to prevent unauthorised operation. The MPF units are available with a 316 stainless or anodised alloy body, small fixed reservoirs starting at a 100cc clear unit and are fitted with a pressure relief valve but no release valve. Pressures to 100 bar. Inlet and outlet check valves are soft seat and poppet types and the unit is easily serviced. Other reservoirs are available. Contact the factory to discuss our MPF units and your application.

Our MT series cartridge pumps are very small indeed but always need to be mounted in a manifold block. Pressures to 400 bar. The hand pump has inlet and outlet check valves, but needs the reservoir, hold/release valve and relief valve provides separately, either by integrating them into a customer manifold block or connecting discrete components. That will inevitably increase the space envelope. Never the less, a manifold based system using our MT series cartridge hand pump can be amazingly compact for OEM applications.

Contact us to discuss our miniature hydraulic solutions.