Why buy a Micropac MT Cartridge, a MQ CETOP3 Hand Pump or a PPS system builder 316 stainless pump?

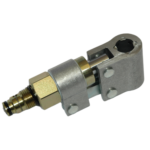

- MT cartridge hand pump mounts into SAE10 C10-2/ C16-2 industry standard cavity

- TM knob actuated C10-2 cartridge pump equivalent to an industry legacy pump

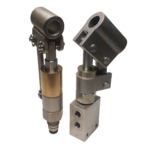

- MQ hand pump mounts directly onto CETOP3 standard manifold

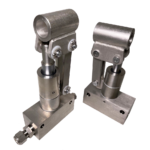

- PPS system builder hand pump mounts directly into pipeline; choice of threaded or Swagelok/ Parker A-LOK connections

- Compact, cost-effective solutions for manual hydraulic power in OEM installations

- Wide range of applications in actuation, testing, braking systems, wind turbines, winches, PSV’s and more

- Choice of materials and sealing to suit operating environment and fluids; 316 stainless versions available

- Removable operating handle can be orientated to suit user position

Which cartridge pump or CETOP pump should I use?

The MT cartridge hand pump screws directly into an industry standard C10-2 or C16-2 cavity machined within a hydraulic manifold block, with tank on nose. Inlet and outlet check valves are integral to the pump body. The removable lever operating handle can be orientated through 360° for ease of operation. The C10-2 version is single acting with models displacing up to 11cc/ stroke at pressures up to 400 bar. The C16-2 version is offered as single or double acting with displacement up to 25cc/ stroke and pressures up to 200 bar.

The unit is also offered with direct knob action on the piston for low pressure applications such as brake release. This version is available configured for pump pressure on the nose and is equivalent to an industry legacy unit.

Materials of construction may be selected to suit operating environment and fluid and there are different sealing options depending on fluid compatibility.

The MQ CETOP 3 hand pump specification is similar to the MT cartridge hand pump but it is designed for manifold mounting and interfaces with a standard CETOP3 footprint. It is typically built into a manifold stack alongside other components e.g. a directional control valve.

The PPS system builder hand pump is also similar in specification to the MT range but is configured to connect directly into pipework, with tank in and pump out. In all-316 stainless steel construction, it offers a no compromise approach to environment and fluid compatibility. It has integral inlet and outlet check valves and pipe connection is via threaded tube adaptor or Swagelok/Parker A-Lok tube fittings. It is intended for incorporation within a hydraulic circuit where there is a requirement for a line-mounted hand pump, alongside other system components from major manufacturers such as Swagelok and Parker.

When wouldn’t you use a cartridge pump, CETOP or PPS system pump?

There is no provision within the pump to release system pressure back to tank; neither is there is any option for an in-built relief valve to prevent over-pressurisation of the system. There is also no provision for mounting a pressure gauge anywhere on the pump body. In the event that any of these features is a requirement, additional componentry would need to be designed into the hydraulic circuit and accommodated elsewhere within the system. Alternatively, explore using one of our other products such as the MW range of single speed hand pumps, which are available with in-built release and relief valves and pressure gauge, range and specification to suit.