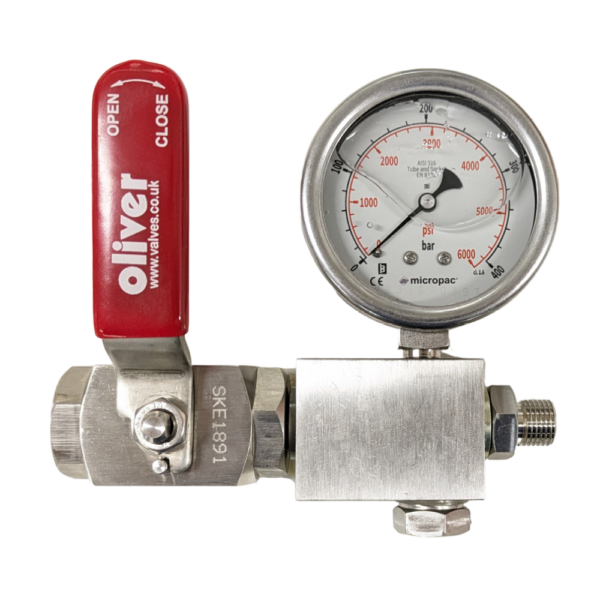

Micropac MSO Pressure Test Lock off Valve with pressure gauge. Locks the test pressure into your test piece.

Why use an MSO Lock off valve?

Whether you are pressure testing on high pressures or low pressures, you need reliability and the confidence that any drop in pressure is due to a leak or permanent deformation of the test piece. By “locking off” your test hose, fittings, couplings and the test pump, you are only measuring the test pressure in your test specimen and have the ultimate insurance that your test results are valid. The MSO valve Locks out leaks and weeps. If you are testing for long periods, you will profit from this extra assurance.

Why might my test pressure drop?

If you are using a Micropac hand pump, you will undoubtedly connect it to your test vessel or part for testing using a flexible hose and hydraulic fittings. A hose will invariably expand as it is pressurised. If you are using several hydraulic fittings and couplings, there is the risk of a weep over time that could translate to a pressure drop in your test piece. Locking off the pressure close to the test item to eliminate most of the possible leak sources cuts the risk.

Do keep in mind that the connection between the lock off valve assembly and your test piece might still be vulnerable to a weep, as would be any bleed valve on your test piece. Also be aware that as your test fluid changes temperature, it will expand or contract and change the pressure by an amount. Take pressure readings at the same temperature if possible.

How can I avoid weeps in my pressure testing set-up?

This is a risk. Over many years of experience, we would say cut the number of fittings to a minimum. Use single piece adaptors rather than making it up from two or three pieces. Be aware that many hydraulic adaptors use metal on metal cones. They need to be tight enough and won’t tolerate damage. Some use elastomeric seals which will be inherently more leak free provided the seal is not damaged. Be wary of worn quick disconnect couplings particularly if you are looking for very high leak integrity. Don’t cut corners by using male tapered threads screwed into straight female fittings sealed with PTFE tape. Our MSO shut off valve is cutting the number of potential leak points on fittings to a minimum by locking them out of the test system, so cuts the basic risk of leaks.

Can I avoid test pressure fluctuations due to changes in ambient temperature?

The answer is no unless you measure pressure at the same temperature. Changes in pressure due to temperature may not be enormous but should be considered. Our experience over many years is that the pressure swings between night and day as a workshop warms up can be appreciable.

Should I be worrying about small pressure losses at high pressure or low pressure?

Although you might think that leaks occur at high pressure, we would say that low pressures can be equally challenging. The leak mechanism is probably just different. High pressure leaks can be far more dramatic failures rather than low pressure weeps. Seals that may fail at low pressure might seal well enough at high pressure. We suggest doing a thorough testing cycle at both a sensible minimum operating pressure and high pressure to ensure components are assembled correctly and withstand the full range of operating loads.

How can I detect small leaks?

Chasing down a very small leak is very demanding. If you have detected a pressure drop over time and aren’t quite sure whether it is your test piece or the run of hose and fittings (or indeed the pressure test pump) that might have a weep, you need to be quite organised.

First leave the system pressurised for a period and assuming you are running on oil or water, see if there is any wetness on any of the fittings. On water, rubbing your finger below threads will often detect very small weeps. That is the easiest action.

Testing the feed hose on shop air is a second method of attempting to diagnose weeps. Using a leak detect spray, such as soapy water will be very effective in visualising leaks. Don’t be over-enthusiastic with leak detect spray. Sometimes care is needed to catch the weeping fittings correctly and allow fluid into the leak path and form bubbles. Don’t expect massive bubbles. Sometimes a foam of very small bubbles will form over five minutes and indicate a small leak.

Using our MSO lock off valve and gauge does allow you to eliminate the anxiety of any weeps in the feed hose, fittings and test pump.

What sort of pressure gauge can I fit to the MSO shut off valve unit?

63mm borden tube pressure gauges are still our starting point. 1/4BSP connections is standard with larger BSP plus NPT connections as options.

100mm diameter pressure gauges with higher accuracy are an option, as well as individual calibration certificates traceable back to National Standards.

Electronic pressure gauges and test gauges are also an option. Talk to us about drag pointer pressure gauges and electronic gauges that record a maximum reading at the start of a test.

Learn more about what ranges of pressure gauges are used.

Why is my pressure gauge leaking at its connection and awkward to seal?

Over many years, we have found copper washers to be the most reliable means of orientating a gauge to the correct position AND sealing it solidly. If you have a pressure drop, this is the first place we would look. Add extra washers to orientate the gauge to the correct viewing position. Don’t orientate the gauge and find it just about seals. It is sure to leak.

Adding a swivel gauge adaptor that can be orientated to the correct position or an excellent Minimess fitting can be worth the money. The Minimess fitting allows the gauge to be removed easily for security and recalibration. The one proviso is that you are adding more cost and extra possible leak points. On balance, a proper swivel gauge adaptor is a good investment.

Will a pressure gauge record the same reading if mounted on the Micropac hydrostatic pressure test pump, the MSO shut off valve or on the test specimen itself?

Once a system is pressurised, there is no flow hence no pressure drops. Accordingly, the pressure is the same at any point. Be aware that two pressure gauges will very probably read slightly different readings yet still be within tolerance. Quality people would designate one gauge an “indicator” and another the measuring instrument.

How can I buy a MSO lock-off valve?

Contact us to discuss your application or for a quotation. We have been designing and manufacturing our Micropac pressure test pumps for 40 years. We are the experts.

Share This!

Related Products

Technical Specifications

| Pressure: | Up to 400 bar working pressure |

| Materials: | 316 stainless steel housing, 304 stainless steel filter element |

| Fluids: | Oil, water, sea water, kerosene, ‘skydrol’, glycols etc. |

| Connectors: | Standard AN -6 JIC male |

| Filter: | Standard AN6235 -1A size filter element |

| Filter options: | 3µm standard, other filters available – contact us |