Specifying a standard hydraulic pressure gauge manometer range makes life so much easier.

After 40 years, we think we are finally getting to grips with which ranges are standards in what country.

We thought we understood it but even now still struggle every time somebody tells us the range specified is not available.

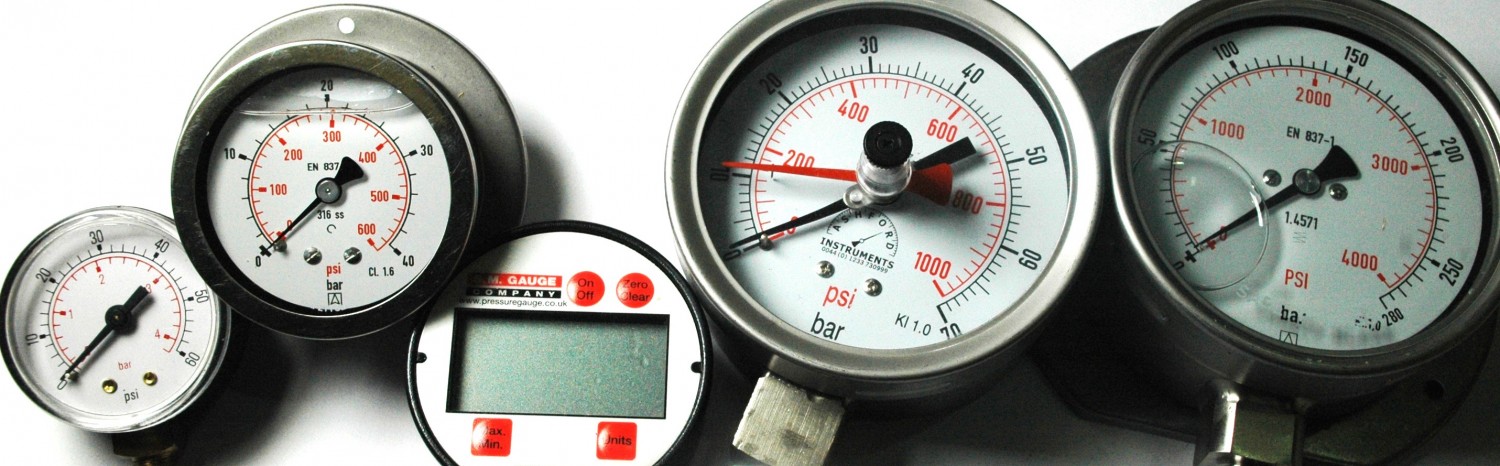

Our Micropac pumps are used on pressures between a few bar and 1000 bar (or 15,000psi). If you are pressure, proof or burst testing using Micropac pumps, a hydraulic pressure gauge is a must. If you are calibrating, you obviously need to know the pressure. Even if you are charging or simply “pumping”, it would be quite reckless to carry on oblivious of the risk of damage or bursting something. Yes, a hydraulic pressure gauge or indicator is quite basic to hydraulics. Let’s check terminology. Pressure gauge = manometer here.

Pick your range.

Your first requirement is to specify a range in psi (pounds per square inch) or in Bar. One bar is 14.504 pounds per square inch. You may also find metric gauges “graduated” in kilo Pascal (or thousand Pascal), where Pascal (Pa) is the SI Metric unit of pressure measurement. 100 kilo Pascal is equivalent to 1 bar.

In the old days, if you were buying US gauges from somebody like Ashcroft they would be imperial and gauges from a European manufacturer like Wika or Badotherm would be based on bar. Imperial or metric gauges would very probably have a dual scale in the corresponding units.

Imperial gauges would typically be in 1000 psi jumps, normally missing out 4,000, 5000, 8000 and 9000. Or at least that is what the catalogue says.

Homing in on European gauges. Metric gauges are invariably based on the DIN EN 837 standard which sets out

Pressure ranges in bar

Based on 6: 0 to 0.6 bar, 0 to 6 bar, 0 to 60 bar, 0 to 600 bar

Based on 10: 0 to 1 bar, 0 to 10 bar, 0 to 100 bar, 0 to 1000 bar.

Based on 16: 0 to 1.6 bar, 0 to 16 bar, 0 to 160 bar, 0 to 1600 bar

Based on 25: 0 to 2.5 bar, 0 to 25 bar, 0 to 250 bar

Based on 40: 0 to 4 bar, 0 to 40 bar, 0 to 400 bar.

Some are really useful. For our pumps, 100 bar, 200 bar and 400 bar are a nice fit with our pump working pressures, subject to our observation later in our post about extended use at full deflection.

In recent years, the European range model hasn’t been quite as universal as it might be. There are a lot of different ranges in there if you are stockholding pressure gauges. As with most volume manufactured products, an awful lot of pressure gauges now come from China. Those will be driven by the US market, so you may well find that, for example a 16 bar pressure gauge that you have bought for years suddenly becomes a 250 or 300 psi unit. Maybe our tip is to provide some latitude in quoting pressure gauges and the risk of being held to a precise range that isn’t available.

The right pressure gauge selection for the application.

We are fretting about finding the right hydraulic pressure gauge range for the job, but what are we worrying about?

Firstly, we would say use enough of the scale to make it worthwhile or meaningful. It would seem imprecise to fit a 700 bar gauge on kit that is only working to 50 bar, although subject to what accuracy of measurement you want, the gauge may be doing its job. In passing, we have frequently fitted low and high range gauges in the same system with a gauge over-pressurisation valve from Schneider. Talk to Ashford Instrumentation on these. An electronic pressure gauge will give you better resolution at low pressures, so that may be a benefit that counts on your job.

Secondly, if you are using pretty well the whole range and say running a 100 bar gauge to 100 bar with the operator limiting the pressure, it is inevitable that they will over pressurise the unit at some point. If you are using one of our Micropac MP pressure test sets, looking at the test piece plus keeping an eye on the gauge, you could over-pressurise. For this reason, we invariably fit a relief valve to limit the pump pressure.

Thirdly, try not to use gauges right up to full range (or “full scale deflection” normally abbreviated to f.s.d.) A 100 bar gauge repeatedly used to 100 bar risks fatiguing the bourdon tube, so we were always told. Two thirds or three quarters of the range used might be better practice. This said, using a Micropac hand pump to full range on a hydraulic pressure gauge will be a lot less punishing than a power pack with rapid pulsations on the tube and gauge mechanism. That would be quite destructive for the bourdon tube.

Note we have not mentioned accuracy here. This will be stated as a percentage of fsd or full scale deflection. Look at what the manufacturer or supplier quotes. Manufacturing standards will state certain accuracies. If there is a need for a particularly accurate gauge, this may drive you to need a 100mm or 150mm gauge. Or maybe an electronic gauge. As with everything, read what the customer has specified.

101 different types to choose from once you know the range.

And where do you start on understanding all the variations on hydraulic pressure gauges and properly specifying what you want? You could write page after page. Connections, size, gauge diameter, connection position, accuracy class, calibration, materials, damping, case type and so it goes on. Talk to a specialist like our friends at Ashford Instrumentation. Our only tip after all this time is that buying a cheap and cheerful hydraulic pressure gauge is a false economy if it fails and the warranty cost to your business is substantial. We just would not risk it. It seems to us ridiculous that so many gauges are bought because of low cost.

Do I need a calibrated pressure gauge or “for indication only?”

This is very basic for gauges and any measurement kit. If it isn’t calibrated relative to a National Standard, it could be miles out. If you can live with that risk, mark it “for indication only.” A calibrated pressure gauge will slot into your calibration system, with a serial number engraved on it and a calibration interval. Do be aware of the difference between calibration traceable back to National Standard and calibration by a UKAS laboratory. A customer order or specification may require a UKAS calibrated gauge at higher cost.

Easy connection.

Standard connection sizes in the UK are BSP male, sealing on the nose using a copper or alternative sealing washer. G1/8 is common for air pressure gauges as used on your shop air and G1/4, G3/8 or G1/2 on hydraulic pressure gauges. Check carefully on what connections are available for what size and range. A G1/4 on a 100mm gauge will be special manufacture and not a good choice unless there is a compelling reason. Even on 100mm diameter gauges, don’t presume that both G3/8 or G1/2 will be available throughout the whole range. Adaptors are available but can be bulky on length and make the gauge assembly more vulnerable. Sometimes, needs must. American hydraulic pressure gauges will invariably be NPT which is a taper thread. In Europe you will find BSP “Gas” connections and metric threads. NPT is quite widely used in the UK. All we would say is to be careful of cold welding of NPT taper threads in 316 stainless whilst trying to orientate a pressure gauge. Maybe a gauge fitting that has a swivel in it is a better option.

If you need to take the gauge off for recalibration, you need easy. On a lower connection pressure gauge, you also need to be able to easily orientate the face to be able to see it. We look for easy removal, simple orientation and an auxiliary outlet as well. We manufacture our own 316 stainless gauge banjo because we couldn’t source one. It is slick. Another option is a Minimess or similar gauge fitting with a Minimess specific fitting for the gauge or hose plus gauge. This allows a pressure gauge to be connected and removed very quickly. Different seal compounds and fitting materials are available. Hydrotechnik are our port of call.

Easy to find “kits”.

A hydraulic pressure gauge “kit” is great for the right application. You have a pressure gauge, a test hose and couplings in a neat carry case from somebody like Hydrotechnik or Stauff. That can be just the job on a large site or where you need to work between a number of test points or connectors, checking the pressure on each.

Why not electronic?

Why haven’t we short circuited this whole discussion by saying “use an electronic hydraulic pressure gauge?” Bourdon tube “old style” hydraulic pressure gauges are still massively entrenched. Why? Is this strange in a tech world? Low tech still triumphs over a device with a battery and will continue to do so in our world. Yes, electronic measurement is massive in control and instrumentation where pressure readings are just one parameter to be monitored in a complex system. For low tech and inexpensive monitoring of pressure with a reading visible all the time, we think traditional hydraulic pressure gauges still have a lot of life in them.

We sell an increasing number of electronic pressure gauges, mainly from the Hydrotechnik range. We did use another major manufacturer and found that the plastic case was very prone to damage in everyday use. In addition, customers seemed to damage the case during fitting of the gauge. For Sarum Hydraulics, we find the “peak reading” facility very useful when installed on our Burst Test units. That said a drag pointer gauge is still a good call. Also keep in mind the increasing number of electronic pressure gauges that are offered with a digital output via a usb connection. This allows instrumentation folk to integrate our manual hydraulics into a more complex system.

Our Micropac pumps allow very easy pressure measurement.

Whether you are proof testing, burst testing, calibrating or just need to monitor a system pressure, hydraulic pressure gauges are very widely fitted to our Micropac hydraulic hand pumps and test units. Fit a hydraulic pressure gauge to your carry-round Micropac MP test set for your pressure testing. Fit one to the manifold on your system incorporating our MT series cartridge hand pump. Talk to us about these or lots of other applications for our Micropac pumps and hydraulic pressure gauges. Contact us or call to talk through your applications with the experts on +0044 (0)1722 328388.

Web resources.

A basic explanation on accuracy and pressure gauge classes. https://www.brannan.co.uk/knowledge_base/pressure-gauges-accuracy-explained/

A good WIKA data sheet setting out the various classes and accuracies. Quite intense, but it is all there.

Our long-standing gauge supplier, Ashford Instrumentation. Good people.

Long established European Gauge manufacturers are WIKA and Badotherm.

I like that you provided some tips on how to select pressure gauge ranges such as considering purchasing easy to find kits. It’s recommended that you shop around for a kit that includes all the basic components such as a pressure gauge, a test hose, and couplings. This would be very practical and convenient to carry as it is very much portable. If I were to purchase my own pressure gauge, I would definitely take this into consideration. Thanks.

Bobby, Thank you for your comment on our Pressure Gauges blog post. Time is money and it is not efficient to spend longer looking for a gauge and fitting than actually doing the test.

Useful page but I notice a mistake in the first paragraph in the Pick Your Range section. 1bar is 100kPa, not 1000kPa.

Kind regards.

Andrea, Thank you so much for pointing out this careless error!! I am pleased that you found the article useful.

Hi, i deal with used heavy equipment like Excavator, Dozers, Wheel loaders, compactor, cranes etc. Mostly CAT, Sumitomo, Komatsu, Kobelco, Hitachi crawler excavators. The main part of these machines r hydraulic pump which r very tough to deal with. Often we cant find out the problems with in it. Can ur pressure gauge could be useful for us?

Plz advice.

Good morning Mahfuz Mahfuz, Thank you for the comment. We are fans of Minimess test points from Hydrotechnik on https://www.hydrotechnik.co.uk/minimess®-1620-test-point . Stauff are another good supplier. You fit these test points in the system and can very quickly connect a pressure gauge to diagnose what is happening in your system. They are very useful for diagnostics. John Foster

Thanks for mentioning that if pressure gauges aren’t calibrated close to a National Standard then it could some miles out. I think it’s a good idea that an industrial factory has gauges that are properly calibrated for national regulations. It also seems like a good investment to hire a reputable company to provide high-quality equipment in order to provide proper readings.

Thank you, Jesse. Thanks for the read and thoughts. You are right. We have a great pressure gauge supplier. They have helped us again and again. Ashford Instrumentation on http://www.ashfordinstrumentation.com/ John Foster

Hi, Your article is very much informative. Can we use this hydraulic pressure gauge for low-pressure applications, pressure spans under 12 psi ? Because in this range it do not generate enough force in the Bourdon tube to operate the multiplying mechanism. Thanks in advance.

Thank you for reading the article, Dime Marine. We are not specialists on pressure gauges, but we think that at very low pressures, there is a capsule construction that is specified instead of a Borden tube type. Or use an electronic gauge. That has got to be a good point that at very low pressures, the mechanism will cause problems on accuracy.

Really, this is an informative blog on Gauges Material. Choosing the best gauges is a great challenge for everyone right now!

Like!! I blog quite often and I genuinely thank you for your information.

like!! I always blog and I sincerely thank you for your knowledge. The blog really increased my curiosity.

like!! I always blog and I sincerely thank you for your knowledge. The blog really increased my curiosity.

I’m thankful that it’s a very helpful blog and it’s knowledgeable.