We are not hose specialists but know a lot about hoses, fittings, valves and couplings. We can supply hydraulic hoses, hydraulic fittings, valves and quick disconnect couplings for use with our pumps.

Which hydraulic hose do we specify?

After 40 years, we certainly know our hoses.

For the relatively low flows from our hand pumps, we tend to specify -4 size hoses with 1/4BSP female swivels on each end then specify adaptors to customer requirements. We try to avoid using -6 or -8 hoses directly on our pumps as they are bulky to store and needlessly heavy for the flows that we are providing. Our default hoses would be steel wire reinforced material. For more demanding fluids or where there is a chemical compatibility issue with rubber hose, a stainless overbraided PTFE hose is a very high performance product with two provisos. A stainless overbraided PTFE hose has a limited pressure rating, depending upon the manufacturer. Pay attention to this. Also be cautious on bend radius and kinking. The convoluted PTFE hose materials have very good bend radii and are a delight to use. The price is slightly higher than smooth bore material. Users can quite easily kink smoothbore material, so we have found over the years.

At higher pressures, thermoplastic hoses are a good choice. At very high pressures (by our standards) of up to 1000 bar, Polyflex have traditionally been our hose of choice. One observation on “specialist” hoses, whether high pressure or special materials is that global manufacturers increasingly offer long lead times and minimum order quantities for the hose material. Beware. That can make PTFE a good call, subject to maximum pressure. Also be careful in selecting exotic end fittings for hoses. Our formula of using a BSP female swivel then adding whatever adaptor is required isn’t a bad strategy.

Contact us to see what we can offer for your application.

Which hydraulic valves should you use?

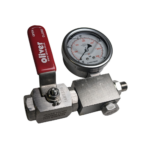

Most of the valves that we supply are 316 stainless and on the end of a hose or close coupled to the pump body. Ultra low cost ball valves from the Far East aren’t our thing. If we use a high pressure ball valve, it will be Oliver or Swagelok. We also use a Hoke 4-way ball valve that is very high quality. Needle valves, check valves or relief valves will be Swagelok or BIS Valves.

Contact us to discuss requirements.

What have we learned about hydraulic fittings and quick disconnect snap couplings?

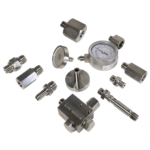

The biggest thing we have learned over 40 years is to try to use single piece rather than making up two or three piece to achieve the same thing. A bulky fitting with multiple leak paths is vulnerable. There are plenty of specialist fitting suppliers who will fill in gaps in standard ranges.

Some of our fittings are bought in from quality suppliers like Flow Technology, Pegasus Hydraulics or Custom Fittings who manufacture very good 316 stainless fittings. Hydrasun in Aberdeen are a great source. Don’t forget Swagelok, who do offer a good range. Or look what we offer. Other fittings are ones we have to make ourselves, so look at these.

For example, if you require a -4 to -10 JIC male male in 316 stainless, we would get it made. Don’t try to get fittings made unless you have the thread gauges. UK suppliers will make these economically and probably cheaper than two or three pieces. Over many years, we have been great fans of Swagelok double ferrule fittings on the basis of quality and sheer pleasure to use. Read our white paper on double ferrule fittings.

We do supply quick disconnect (“Snap”) couplings. Over the years, we have tended to be fans of Snap-Tites (now part of the Parker range). Everybody has their own favourites. The only observation we would make is that seals in these do wear and using them in very high integrity/low leakage systems over many years can be a big ask. It depends how many times they are being snapped on and off.

Try to be unambiguous in describing quick disconnects. The Americans would say “male probe” and “female coupler” and the sizes. Buying the wrong half is hopeless.

As always, never run a fitting at higher than its rated pressure.

We would always say buy in the correct fittings for the job and try to keep them as a kit labelled up for the job. The cost of searching for fittings is more than the fitting itself.

What material would you use for water hydraulics?

If you are working on water, we would say use 316 stainless rather than carbon steel, simply because corrosion is ultimately troublesome. We don’t use brass simply because we worry about pressure ratings and galvanic corrosion. There is a place for brass.