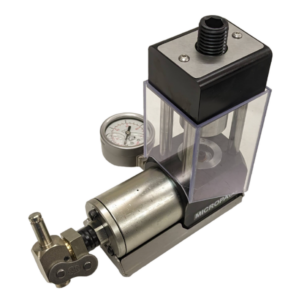

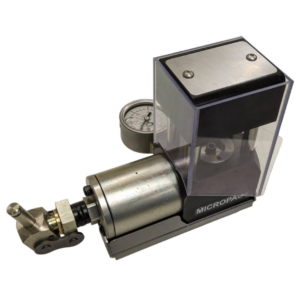

MLP10 compact, precision laboratory and shop press

Why use our MLP10 10 tonne compact precision laboratory, field and shop press?

Our MLP10 10 tonne hydraulic press meets a need for a good value small 10 tonne press for the laboratory, in the field or shop. The unit is compact and can be used in any orientation. That allows it to adapt to meet your exact laboratory or production need. There is an optional pressure gauge calibrated in tonnes and kN. This is protected with a rubber boot, giving extra assurance if the unit is transported or used in the field. The press can be supplied in a rugged transit box.

Who uses compact hand hydraulic presses like the MLP10?

Scientists and technicians are the most common users of this type of press. They may be used for a specific job in the lab like preparing samples for an electron microscope or for a variety of other lab applications. The small size and high tonnage make the unit suitable for site work such as swaging or field work like preparing geological samples for analysis. You wouldn’t use this type of press for production work that was very repetitive. A production engineer would invariably speed the process up with a powered unit.

What is different about the MLP10?

The unit offers good value compared with mainstream scientific products. We are providing a rugged instrumentation-quality product within our range of Micropac industrial hydraulics. Like all our equipment, this product is manufactured in our UK factory. Users told us they wanted a miniature press that they could flip onto its back with the axis of travel parallel to the bench. That makes it easier to use for many people and also opens up different applications. Talk to us on any specialist saddles for this press for your own specific application. The unit is easily serviced with inexpensive parts from us, the manufacturer. After over 40 years, we are the mobile hydraulics experts.

Is a powered press better than a hand hydraulic press?

The answer is not necessarily. As with all equipment, getting the right tool for the job is the most important. For certain jobs, this type of hand hydraulic press is perfect. Off site or in the field, you want a compact hand unit. Even in the lab or factory, a hand press provides a flexible tool for lots of jobs. Safety is also a big consideration. A hand press needs considerable care, although a general point is that the operator simply stops pumping if there is a problem. Move to a powered press and you will need to risk assess every application. A powered press needs guarding and interlocks to ensure that an operator’s hands cannot remain in the press while it is operating. High tonnage presses and always dangerous pieces of equipment. Powered presses are highly regulated.

If you have a production process running thousands of times, a production engineer will invariably go to a powered unit.

Can I use the MLP for low loads?

Yes, you can use the MLP10 at substantially lower loads. We can set the internal relief valve at a lower pressure for you as well. A non-standard pressure gauge calibrated at a lower force can be supplied.

Is the MLP10 a 10 Imperial Ton press?

10 Metric tonnes is 11 US tons. 10 tonnes metric is 9.84 imperial tons and 98.1kN force.

Is an integral press better than a 700 bar cylinder in a frame and separate pump and hose?

Manufacturers like Enerpac and Hi-Force do supply presses with a cylinder mounted in a steel frame then power the cylinder using a pump/reservoir and a hose. These provide flexibility over a very wide range of jobs but certainly aren’t ultra compact or the sort of thing you would take into the field. The 700 bar pressure rating on this type of equipment is very useful in providing a formidable force to weight ratio. That is the reason it is used world-wide from lots of manufacturers and why we use it on our presses and jacks as well.

What type of piston rod and saddles does the MLP10 use?

The hard chrome plated piston rod is fitted with a hardened carbon steel saddle, as is the platen above it. These saddles are easily swapped out and could be replaced with custom designs for particular applications.

What is the basic MLP stroke and gap?

The basic model has a stroke of 35mm and a gap of 32mm. A long stroke model is available with a threaded adjuster that can be preset. This provides a maximum gap 50mm. There is a spring return on the ram rod so that it retracts back into the body if the pressure is released. Consult our data sheet.

Has the MLP10 hand hydraulic press got a pressure relief valve to limit the maximum pressure? Is there a safety window on the MLP10 press?

The hydraulics are based on our JAK10 jack and include a precise hold/release valve and an adjustable relief valve. There is a neat base for bench mounting. A sliding removeable polycarbonate safety screen is fitted for protection in use.

Share This!

Related Products

Technical Specifications

| Pressure: | 700 bar |

| Stroke volume: | Closed height 76mm/lift 35mm |

| Materials: | Carbon steel |

| Seal options: | Standard Nitrile seals |

| Fluid options: | Prefilled and seal mineral oil hydraulics |

| Other options: | Pressure gauge graduated in Tonnes / kN |