Making sense of eco hydraulic fluids, synthetic fluids and water in the search for alternatives to mineral oil

Are pure water or vegetable oil the perfect eco hydraulic fluids?

So, can I run my eco hydraulic system on vegetable oil? What about running my hydraulics on water from the tap? The answer is yes, but depending upon what you are doing but more likely you will need a cocktail of additives for it to work. And that opens up the chemistry of synthetic hydraulic fluids and buying a drum of proprietary fluid with its complex mix of additives. There may be a lot of reasons to wean ourselves off mineral oil, but it is hard act to follow and alternatives are not simple. But there are alternatives. Read on.

Sarum Hydraulics has a lot of experience with different fluids in hydraulics. Our very first customer back in 1982 was running hydraulic trench shoring using tap water. In the subsequent 40 years, we have seen lots of different fluids and generic types. Mineral oils, other hydrocarbons, solvents, phosphate esters, water glycols, emulsions, water, exotic barrier and heat transfer fluids and a lot else. Our starting point every time is “what are you doing with the fluid under what operating conditions, what materials are in the system and crucially what are the elastomers and sealing arrangements?” And of course, safety is everything.

People do different things with fluids. So, what are you actually doing and under what conditions? Our trench shoring customer wanted to use tap water in the very simplest hydraulic system with a Micropac hand pump and a single acting hydraulic ram suitable for water. Watch our YouTube video if you want to learn some basic hydraulics. At the other end of the scale the fluid might be running a highly complex and safety critical system with powered pumps, valves and actuators in use 24/7 in extreme conditions. We are not going to present an exhaustive guide on fluids with the properties of all the different types. There are plenty of web resources. This is simply our own take.

Can I run my hydraulics on tap water?

Some people do. It is cheap, readily available, fireproof, non- toxic and safe for disposal provided it isn’t contaminated. For example, The Water Hydraulics Company will supply a system for a football stadium sliding cover or other applications where spillage can only be pure water because you don’t want to kill the grass. That is one specialised application, but very soon you have to address the limitations of water.

You can’t get away from pure water being very low viscosity and having poor lubricity. These inherent properties cut out its use with mainstream hydraulic components and requires valves and seals that will work with water. That adds a significant level of complexity and cost to most hydraulic designs. Look for wider applications and you have to start modifying your simple water as a fluid. Add a poisonous biocide to stop biological growth. Lower the freezing point to stop a disastrous winter freeze-up. Add a chemical to fight corrosion. The mix of metals in a system running on water will inevitably give rise to galvanic corrosion, as water will act as an electrolyte. Be careful of not monitoring the pH of the resulting fluid, only to find that it becomes acidic and corrodes metallic components and so on.

By this time, you have a medium that is quite a complicated synthetic fluid and not particularly kind to the environment, although probably kinder than mineral oil (or nasty in a different way.) We’ll look engineering water glycols a little later. That is a common way to go on synthetic hydraulic fluids, but always seem quite a long way from the dream of using water out of your tap.

Can I use vegetable oil as my eco-friendly hydraulic fluid?

If you had the simplest hand pump pressurizing a single acting cylinder, maybe you would get away with it for a while. You wouldn’t fill your electric hydraulic power pack with vegetable oil from the can unless you were in the direst human emergency. In reality, a vegetable oil based hydraulic fluid will be blended with additives and will be quite a complex mixture. For example, your kitchen vegetable oil oxidises to that brown sticky sludge over time, particularly with heating. That isn’t tolerable in a hydraulic fluid for normal use in contact with air.

Similarly, the pour point is relatively high with the vegetable oil becoming very viscous down at zero degrees C. That said, benefits are that the oil is biodegradable and relatively safe subject to the additives used. Automotive braking systems used to employ castor oil based hydraulic fluid, but even this was quite a complex synthetic fluid with numerous additives to change this or that property. That goes right back to the earliest hydraulic brakes. Vegetable oil based fluids are still there, for example Houghton’s Cosmolubric fluids, derived from rapeseed oil plus additives. The “esters” here are natural esters. In passing, “esters” which appear in the components of vegetable based fluids shouldn’t be confused with “phosphate esters” or indeed the synthetic esters that are the building blocks in synthetic hydraulic fluids.

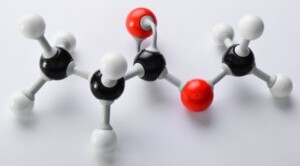

What is a synthetic hydraulic fluid?

The starting point is that the synthetic hydraulic fluid is not based on hydrocarbons. Despite a vegetable oil based hydraulic fluid needing extensive additives, it seems this isn’t termed a synthetic fluid. Feel free to correct us. A water based fluid that is highly engineered with additives to enhance properties effectively becomes a synthetic fluid. The fluid has actually been crafted and probably has a trade name. A synthetic hydraulic fluid can be manufactured for optimum properties for the job in question. For example, controlling the viscosity over extremes of temperature, wear resistance, anti-foaming or very low toxicity may be specific features out of hundreds of permutations.

What is a hydrocarbon based hydraulic fluid?

Crude oil is refined and a massive range of compounds produced at different stages. Mineral oil is one product. Manufacturers will blend the fluid with additives to enhance properties such as wear resistance, viscosity, foaming, corrosion and so on.

What are the benefits of hydrocarbon based hydraulic fluids?

There is a massive range of mineral oil based hydraulic fluids. Just some of our shop fluids.

The downside may be cash cost depending on your alternatives, dreadful environmental damage at a larger scale, fire risk and the environmental nightmare if you have a spill. The whole business of extraction of this fossil fuel, its processing, distribution, use and disposal has left a massive mark on the world. Being realistic, a lot of the world will be working with hydraulic systems using mineral oil for a long time. And the world would still have a massive appetite for hydrocarbons to produce other products even if our industry ran 100% on eco-friendly fluids. Nevertheless, the hydraulics industry needs to be using alternatives. There are lots of reasons to make that happen.

What specialist synthetic hydraulic fluids are used?

A very wide range of hydrocarbon based and synthetic fluids with massively different properties

These are split up into three categories. Specialist manufacturers have extensive reference material on the web, for example https://www.valvoline.com/en-eur/hydraulic-oil/ Sub dividing types into more precise categories is quite involved.

Water Glycol synthetic hydraulic fluids were early alternatives to mineral oil. “Houghto-safe” fluids are one leading product. We have supplied our Micropac handpumps tested on these. They are widely used, particularly where there is fire risk or mineral oil is an environmental hazard. For some decades, mining and steelmaking (to name just two industries) have adopted these fluids. Bear in mind that the water content will evaporate. Their temperature range is also limited. From our perspective, we note that Engineers worry greatly about long term corrosion and normally order stainless steel pumps.

Keep in mind that “water glycol” covers a wide range of fluids, one of which may meet your criteria. A water glycol offshore control fluid like Oceanic HW540e is a very low viscosity medium and at the other extreme of viscosity, OX40 and similar water glycols are widely used in place of mineral oil in marine and industrial systems. And don’t forget that automotive braking systems commonly run on water glycol based fluids.

Polyol Ester based synthetic hydraulic fluids are commonly used as alternatives to mineral oil. They offer good performance and easy conversion. We have supplied pumps for specific use on these fluids. Again, consult web resources from the major manufacturers.

Phosphate Ester aerospace hydraulic fluids such as “Skydrol” have been in use since the 1950’s. They are a well-resourced synthetic fluid. The main benefit is being fireproof. Read our white paper to learn more. Our pumps have been used on this fluid for aerospace GSE applications for many years, so we know it well.

Skydrol is a specialist aerospace phosphate ester

Can I use Silicone Oil as my hydraulic fluid?

Silicone oil is used in some specialist applications. People use it for damping and a minority of automotive braking systems use it. It seems to have limited application. Again, the web will have the answer.

How difficult is it to see what a synthetic hydraulic fluid or a solvent/barrier/heat transfer fluid has in it?

Some fluids properties are a puzzle even for a chemist

You need to know what is in a synthetic hydraulic fluid or your hydraulic medium to check your system has compatible materials and to ensure that the sealing elastomer is suitable. Some fluids are quite easy. You can see the generic name (like “skydrol”) and see the optimum seal compound. Or the manufacturer tells you what it is, for example an HFC water glycol. Others are called a weird name for an exotic cocktail and even a chemist can’t tell you whether elastomers will be dissolved, hardened, swell up or suffer other failure modes. The Safety Data Sheet is quite often unhelpful as the main constituents are listed but these are so specialist that they aren’t listed on seal computability charts. This is a very common problem now for our business. A customer calls with a generic name and we cannot actually suggest the correct seal compound or pump type. Move to solvents, barrier fluids and heat transfer fluids and we find this a dreadful problem.

Can I top up my mineral oil with a synthetic or vegetable based fluid?

Unfortunately, that isn’t the way this works. You are emptying a system, flushing or replacing seals then refilling. You can’t mix and match. Hence the need to get it right.

Where do I start in moving to an eco friendly or synthetic hydraulic fluid?

Coping with multiple hydraulic fluids is the future, so we just hope that web resources from the manufacturers do make it easier to drill down into the full implications on materials, seals and a lot more. Just do remember those key questions to address. How does the fluid react with system materials in the short and longer term? What happens with the sealing materials? What are the lubrication properties for both seals and moving parts. Only then would you move on to numerous other fluid properties such as safety, means of disposal, cost, temperature range, flammability, foaming and so on according to your specific priorities. It is a deep subject. And don’t forget that over riding question as to what is really important for your application.

After 40 years of manufacturing our Micropac multi-fluid pumps, we are always pleased to talk about your specific applications.

Web resources:

This basic guide from Valvoline pulls together a neat summary. There are a good few guides on the web.

Not surprisingly, Houghton also provide a decent guide on fire resistant fluids. Different users want certain things from their fluids.

Seals for Synthetic hydraulic fluids. Something very basic from Panam . You do need to be pretty clear what type of fluid you are using.

Our own Trade Association, the BFPA are another great resource. This publication looks at the bigger picture on hydraulic fluids.

Leave A Comment