Passionate about manual handpump solutions in 1982 and now. Tony Foster testing an early prototype.

In 2022, our Micropac pump was 40 years old. Yet, despite its age it has remained almost unchanged in all those years and it still sells throughout the world.

What need does our Micropac hand pump fulfil?

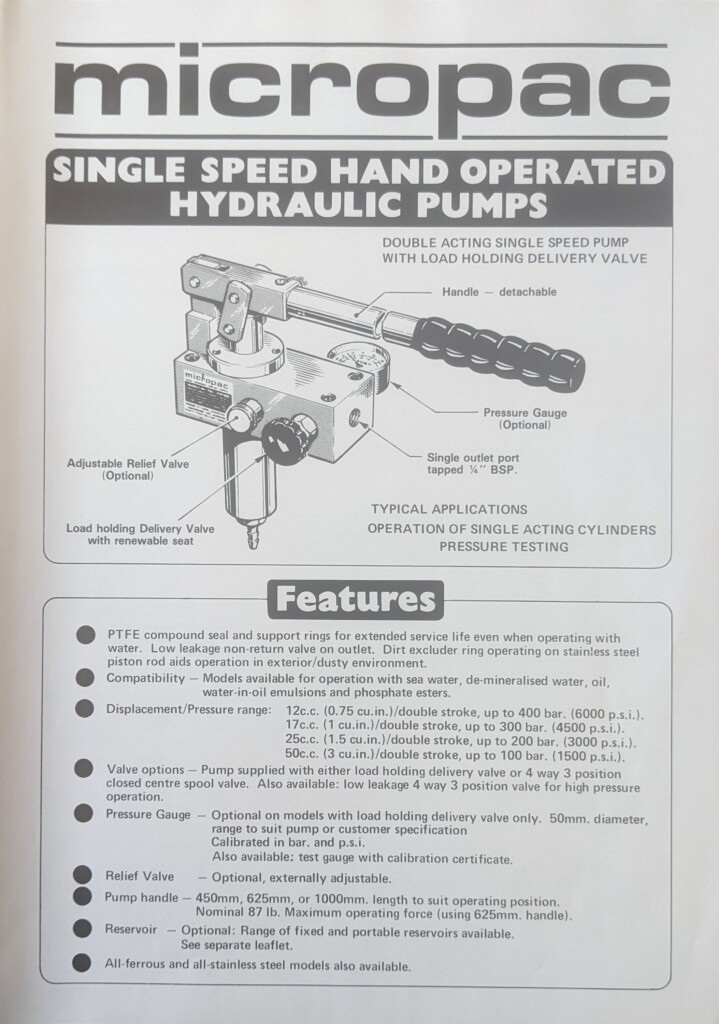

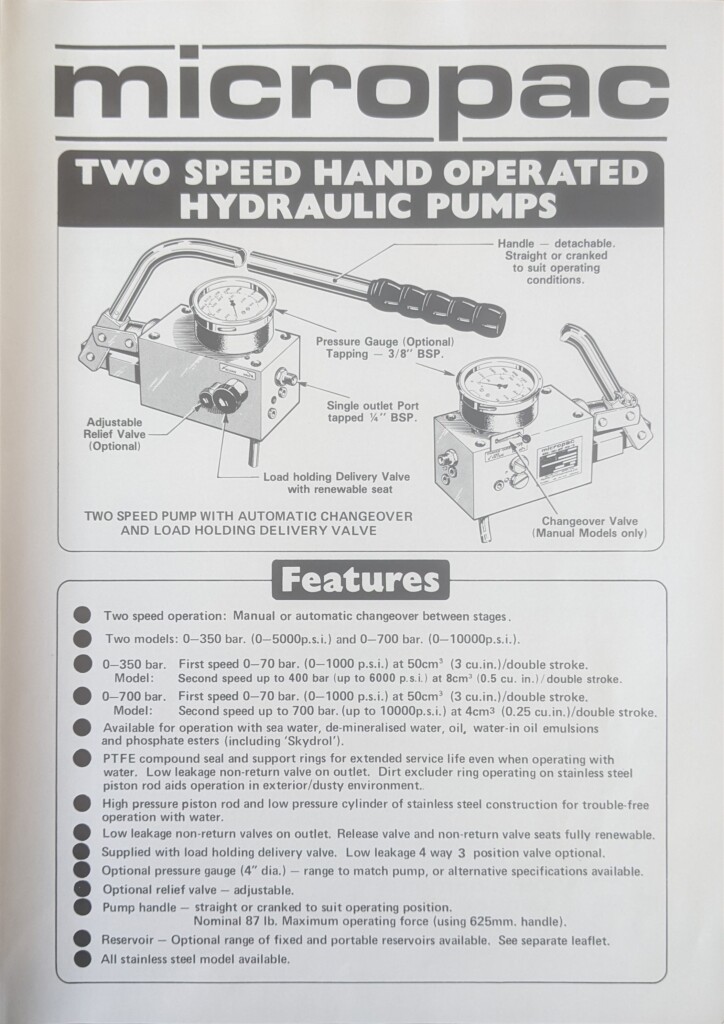

Back in 1982, a customer said that they couldn’t find a hand pump that would operate on water and very thin eco fluids. All the market could offer was units with leaky ball check valves, metal valve seats and units that were corrosion prone then had to be thrown away. Now, 40 years later, we still know it is vital to move away from mineral oil where we can, often towards much lower viscosity fluids. Alas, ball check valves still leak in the wrong application, metal seats have drawbacks and throw-away equipment doesn’t do much for sustainability. Micropac pumps have been there throughout offering fluids other than mineral oil and have been the right product for decades for our customers.

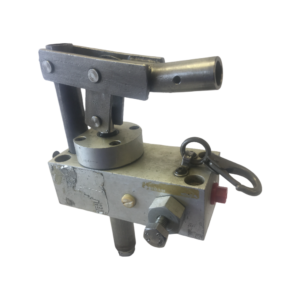

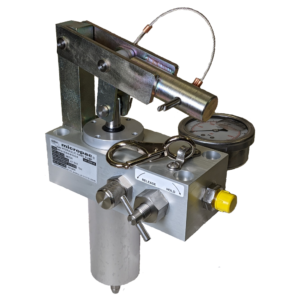

One of our pumps, returned to us for a service from 1982.

Today’s equivalent MW-A Hand Pump

What new market needs have come along in 40 years?

“Everybody has moved to cheap electric power packs or electro hydraulics.” Long live hand pumps. That may sound strange. Cheap electric hydraulic power packs and cheap electric drives might well have hollowed out a chunk of pure manual hydraulics over four decades, but our cheaper cartridge hand pumps have provided tens of thousands of emergency back up hand pumps for the market. There is no doubt that the world has fallen in love with push button operation for lots of tasks rather than manually pumping. Perversely, one odd market movement in the last decade is to revert to hand pumps on presses and machinery where the Health and Safety requirements on powered systems are massively onerous for good reason. A Micropac hand pump offers a failsafe solution. Stop pumping and the machine stops. Lots of designers are increasingly seeing the benefit. And some customers simply won’t even entertain the risk of a flat battery in your hour of need.

What are the Micropac winning features?

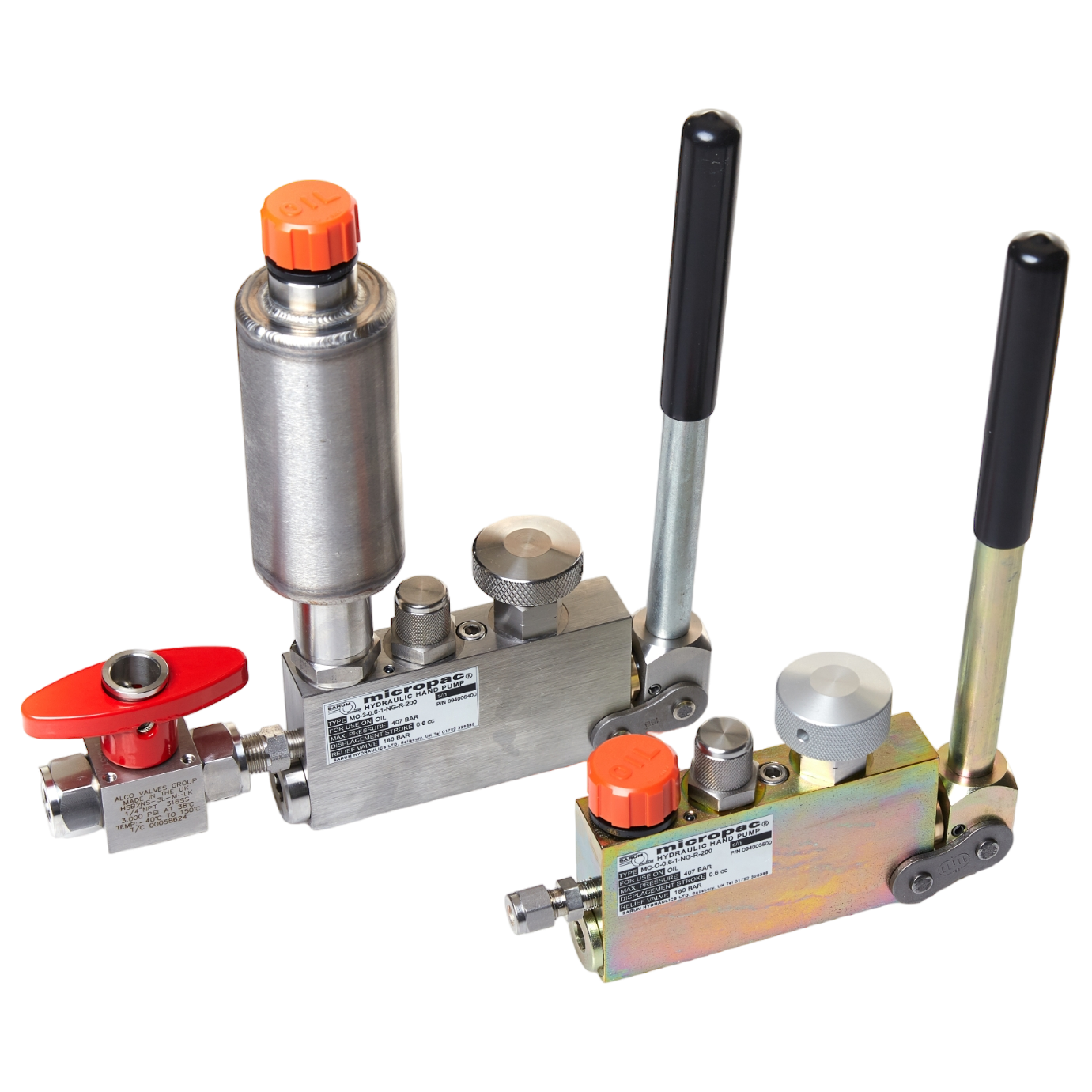

From day one, the Micropac pump was truly multi-fluid. It would happily run on water as the hydraulic or test fluid. We used a hard chrome plated 316 stainless steel piston rod and ran the piston on ptfe bearings in a 316 stainless liner, even on the entry level anodised alloy unit. The check valves are up for the job with a very low leakage poppet outlet check and soft seat inlet check. All the valve seats are replaceable, a great feature back in 1982 when people valued serviceable equipment and an even better feature now in a sustainable world. The Micropac pump has never been throw-away. We also wanted to offer alternative seal options very easily and on short lead time with low cost. That was simply the way we designed our pump. The competition seemed to struggle, trying to use oil service pumps for water and quoting a long lead time on any “special” seals. That seemed to be the way it was. The Micropac pump has also always been great value for money. Just a quality British product from an independent manufacturer passionate about their product

Our Single Speed Brochure page from 1984

Our Single Speed Brochure page from today

Who were the customers then and now?

Early adopters were water hydraulics people or users of low viscosity fluids such as emulsions. Offshore control fluids people also used the pump, as media such as Oceanics are very low viscosity. Oil hydraulics people also came on board for durability and specification reasons. People requiring a lightweight carry-around pressure hydrotest pump started to use the pump as their standard. Fire misting system installers have used our pump throughout the world for years. Thousands or users worldwide just keep a Micropac pressure test pump on their site, shop or hangar for use everyday. They last for years, ready to use when you need them.

And then there were all those bits of kit that were based around a Micropac pump. The list goes on and on. Four specific areas that have been there over the full four decades have been the vgv actuator test unit, API charging systems, hydraulic seats and actuator manual overrides. Each application needed something that the Micropac pump uniquely provided.

The VGV test unit provided an equivalent for a legacy piece of GSE test equipment. They are used daily around the world and continuing use on jet engines such as the new LEAP engine might even give them another 40 years of life.

API charging systems for mechanical sealing systems have been another very big application world wide. The Micropac pump offers legendary “fit and forget” reliability even in the most savage or hazardous environments, so offshore and process plant operators don’t have to worry about seized or corroded hand pumps when they need to pressurise their sealing systems. The pumps are specified in the anodised alloy/stainless or 316 stainless/bronze models and with whatever extras like release valves and gauges are required. The pump is just one component in an API system.

Hydraulic seats are a specialist application, mainly in defence. Micropac pumps and cylinders form rugged seat control on quite a few platforms. Again, customers require “fit and forget.”

Finally, Micropac pumps have been used in valve actuation literally since day one. That explains why an Isle of Wight, United Kingdom designed pump speaks American. One of the first customers was an American actuator manufacturer. Offshore and process actuator people require reliability, high quality and good value if they are manufacturing lots of manual overrides. Forty years has seen our units used all over the world including deserts, tundra, jungle and even under water.

Micropac pumps in the next 40 years.

There will always be a market for a high quality multi fluid hand pump with great engineering support. Customers around the world will still value the product. Indeed, some features such as our ATEX and IECEx Micropac pumps for hazardous areas may well be a niche product, but still represent a significant worldwide market.

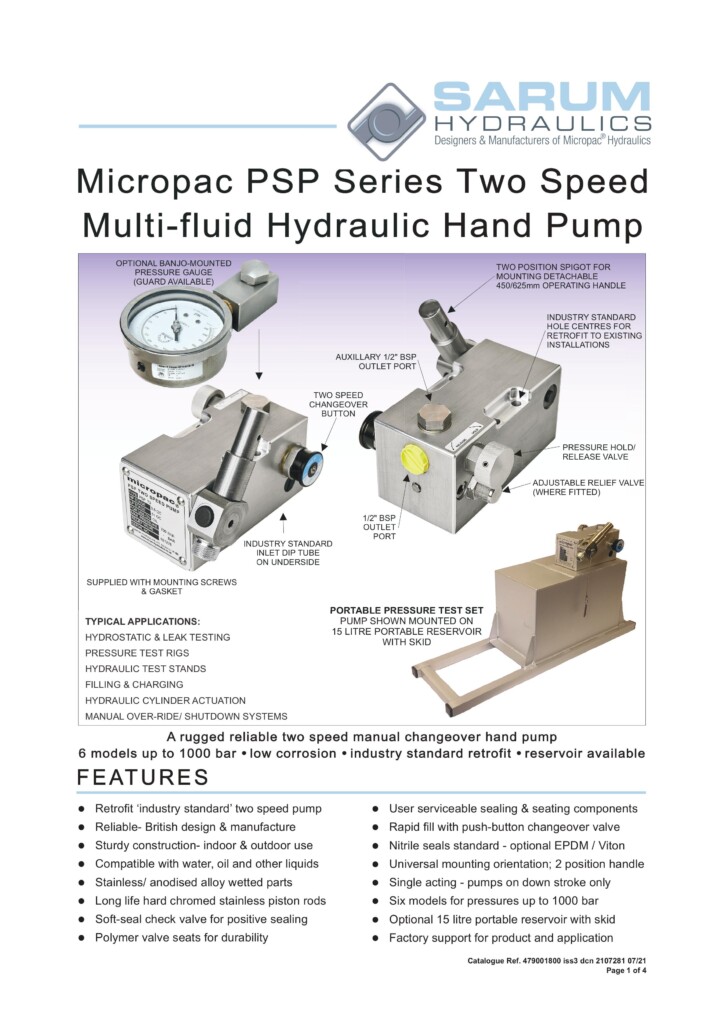

Our Two Speed Brochure page from 1984

Our Two Speed Brochure page from today

Leave A Comment