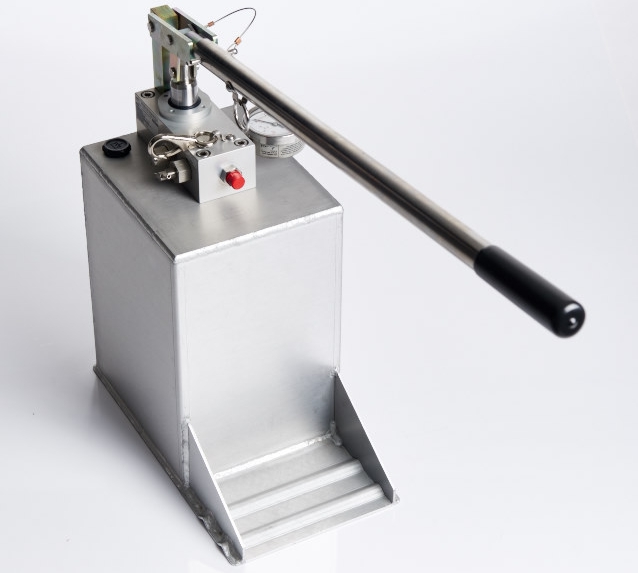

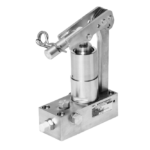

A range of long-life compact pressure test pumps suitable for operation in a potentially explosive atmosphere. Double acting operation. Soft seal outlet check valve; ideally suited to hydrostatic pressure and proof testing. Five models cover maximum pressures from 50 bar (100cc/double stroke displacement) to 700 bar (7cc/double stroke), with a variety of sealing options for different fluids. Supplied with portable 316 stainless reservoirs capacity 5-50 litres, with integral carrying trolley option. Optional pressure hold/release valve, relief valve, pressure gauge and hose. 316 stainless steel and bronze construction.

Why buy a Micropac MP UKEX/ ATEX/ IEC Ex 316 Pressure Test Pump with Reservoir?

- Certified to meet UKEX, ATEX/ and IEC Ex explosive atmosphere requirements

- Inherently safe- no electrical supply required and simple low velocity mechanism

- Rugged, ergonomic and cost-effective mobile pressure test and filling solution

- Versatile- wide range of options to specify the unit that meets your requirements

- Multiple sealing options to suit wide range of operating media

- Long life- corrosion resistant materials of construction and serviceable for sustainability

- British designed and manufactured- factory support for your application

Description

Pressure test pump mounted on portable reservoir. Connect system to outlet port via hose or tube. Fill reservoir with fluid. Operate pump handle to achieve maximum pressure. Compatible with multiple fluids including water, oil, glycol and ‘Skydrol’, dependent on sealing option. Pump is 316 stainless steel and bronze construction with UHMWP, PTFE and a choice of nitrile, fluorocarbon or EPDM elastomer sealing.

Available with pressure hold/release valve, adjustable relief valve for pump protection, pressure gauge (range to order) and hose (length and outlet fittings to order).

316 stainless steel reservoirs with sturdy footplate available, either for hand carrying or with integral carrying trolley, dependent on size and application. Pumps supplied factory fitted to reservoir according to ordering code.

Pumps are coded as follows:

UKEX and ATEX: II 2 G Ex h IIC T6 Gb

Non-electrical equipment intended to be used in Surface Industry classified as both Gas Explosive Atmosphere – Zone 1 and Explosive Atmosphere of Combustible Dust – Zone 21.

IEC Ex: II 2 D Ex h IIIC T85°C Db

Non-electrical equipment conforming to ISO 80079-36:2016 both for EPL Gb for use in explosive gas atmospheres of Group IIC and ignition temperature greater than 85°C, and for EPL Db for explosive dust atmospheres containing dusts of Group IIIC and maximum surface temperature less than 85°C.

If you need further advice, please contact us to discuss your requirements.

All our pumps are serviceable for sustainability; service kits are available from the factory.

For more information on the MP UKEX/ ATEX/ IEC Ex 316 Pressure Test Pump with Reservoir, download a datasheet (see link at bottom of page).

Non-certified versions of these hand pumps are also available; please see our Products and Solutions pages for more details.

Share This!

Related Products

Technical Specifications

| Max. pressure/displacement per double stroke: | 50bar/100cc, 100bar/50cc, 200bar/25cc, 400bar/12cc, 700bar/7cc |

| Materials of construction: | 316 stainless steel, aluminium bronze- see datasheet for full details |

| Reservoir sizes: | Carrying by hand: 5, 10, 20 litres. Trolley: 10, 20, 50 litres. |

| Seal options: | PTFE, UHMWP and nitrile, fluorocarbon or EPDM depending on option |

| Compatibility: | Mineral oil, water, glycol, ‘Skydrol’ phosphate ester. Other fluids; please enquire. |