Rugged, no nonsense, and barely a scrap of corrosion to boot; our MB series low-pressure, high-displacement 316 stainless and polymer hand pump is a serious bit of kit. With this professional component ideal for such a diverse range of fluids, Sarum Hydraulics are increasingly observing customers using our MB series hand pump for fuel additive dispensing systems with a nostalgic glee. If you thought additives were doomed to the age of disco, think again. From cutting edge common rail diesels to pre-historic technology struggling with the eco fuels of today, fuel additives are making a comeback.

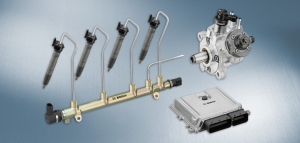

Pundits will tell you that a common rail diesel fuel injection system is a masterpiece of engineering and with their massive pressures and ultra fine tolerances, these demanding systems require sophisticated care. Cheap supermarket fuels are often unable to cut the mustard and keep these fabulous feats of engineering running at optimum performance. The solution has traditionally been to reach for premium diesel fuels such as Shell V-Power and BP Ultimate which are premixed to contain a healthy dose of fuel additives. Providing a “deep clean” effect, the presence of additives in the fuel has become integral to maintaining optimum system performance of these marvellously complex machines.

Increasingly though, commercial operators are taking matters into their own hands. Rather than reach for the typical premium fuels, operators are instead creating their own 70s inspired home-blend cocktails, adding third party additives to their fuel in a bid to improve performance, inhibit corrosion and break up deposits.

Why the sudden return to the age of disco? A throwback to the STP days maybe, but consider a 1000 bar miniature piston pump for diesel duty and solenoid injectors operating at a capacity of 100 million times over their lifespan. Operators need all the help they can get and at Sarum Hydraulics we are always inclined to take commercial users seriously. With so many professionals reaching for the fuel additive bottle, it is time to acknowledge that additives in some form can and will help maintain the performance of a common rail diesel.

But it’s not just common rail diesels receiving the fuel additive treatment. Increasingly, additives are taking on a lethal new role, this time as defenders of marine engines which for years have suffered failure as a result of growing colonies of bugs in the tanks of marine diesel clogging fuel filters and causing engines to stop. Bad news indeed for marine professionals and yachties alike, but a plethora of fuel additives have emerged as a simple and effective solution. At Sarum, we are partial to a local blend from Wessex Chemicals, but with premier fuel filtration specialist Parker Racor now marketing their own offering, anti-bug biocide additives are helping cement fuel additives back in the 21st century.

For domestic gods and goddesses, additives are also proving an essential tool around the home, particularly in heating and cooking where modern eco friendly low sulphur home heating fuels can wreak havoc on old fashioned burners. A small shot of the right additive will allow your boiler or Aga to burn sweetly again. If the fuel tanker is equipped with a dispenser and additives are injected by a few strokes of a Micropac ® MB Series pump? Even better!

The major downside to the home chemistry revival is that in their neat form, fuel additives are noxious fluids, and serious care ought to be taken when dispensing them. For the home user, this is assured via the provision of an ergonomic moulded bottle, featuring an integral measuring cup filled through a tube within the moulding. Whilst invaluable for the home or marine user though, in the case of larger quantities, it is simply not a practical solution.

For the user dispensing larger quantities from a tank or a drum, our Micropac ® MB Series Stainless steel pump ensures safety, practicality and simplicity in the form of a properly engineered dispensing pump, allowing you to meet all your dispensing needs without risking the safety of your, your staff or the environment.

At Sarum Hydraulics, we anticipate the next big test for fans of fuel additives will be the challenge of adding controlled amounts of additives into your fuels precisely on the run. “Dosing”, which involves measuring the levels of the pollutants as the engine runs and then tweaking the amount continuously, as opposed to the traditional “glug”, could be big business on the up. Could there be room for real innovation here?

Sarum Hydraulics loves innovation. We believe that fuel additives are big and could go far beyond the constraints of 1972. Talk to us about how our MB Series 316 stainless and polymer filling and dispensing pump can provide a solution for your fluid system. www.sarum-hydraulics.co.uk

Leave A Comment