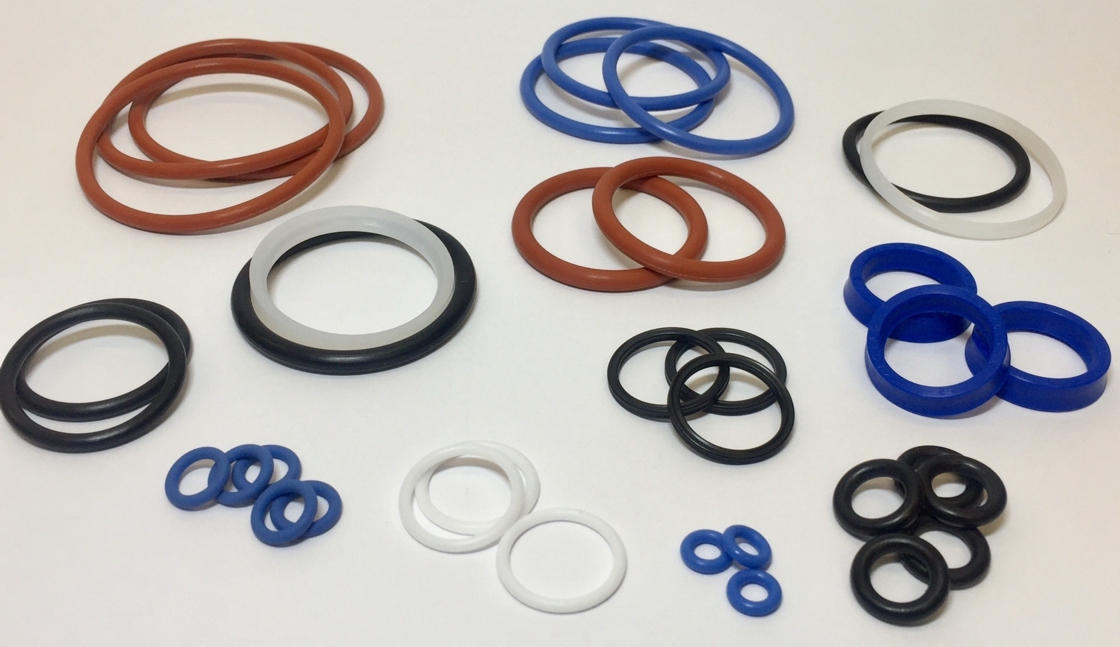

Why do we like U seals? If you don’t need to offer a wide range of fluids and temperature ranges using one size of groove, a U seal for a piston rod bearing can be a great choice. Pick polyurethane (PU) and you have a remarkably rugged seal. The temperature range of down to -30 degrees C may or may not cause problems for you, but DMR can make you low temperature PU U seals to fit in the same groove. Keep in mind that you will need a special grade of PU for water or water based fluids. First port of call on U seals is DMR or FPE.

SERVICE INSTRUCTIONS

Description of piston rod bearing seals

Our MW-3-7 pump and some of our MT series cartridge pump units use a polyurethane U-seal as the main bearing seal. These offer an exceptionally long service life and are very rugged sealing elements. The MW-7 U-seal incorporates an additional back-up ring to prevent extrusion at high pressures.

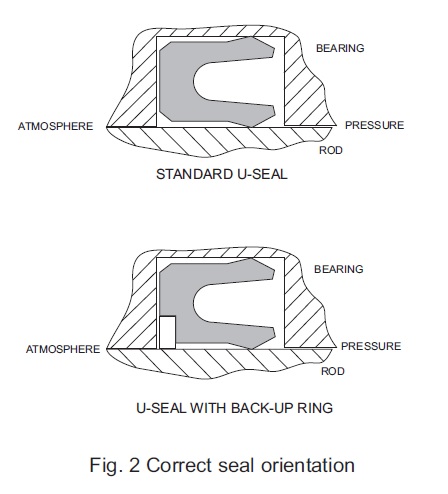

Great care must be taken not to damage this material during installation. Note from Figure 2 that the “U” faces the pressure, so the seal has a direction when installed. It is vital that this is orientated correctly.

On the MW-3-7 with the additional back-up ring, this is installed into the moulded counterbore in the seal after installation. Do not fit it into the groove before the U-seal.

Experience has shown that when correctly installed in Micropac equipment, the seals will give extended life compared with O-rings. Failure is generally due to damage caused by abrasion from the piston rod, where there has been damage to the rod surface during service. In such circumstances the rod will require replacement.

Installation

Inspect the old U-seal for even wear. Any localised abrasion may indicate rod damage.

Remove the back-up ring if there is one, ensuring that you do not damage the metal surface of the seal groove. Clean the groove with solvent and then check that there is no damage. Clean the bearing.

To replace the U-seal, warm the seal in warm water for 5 minutes. The water temperature should not exceed 80 degrees Celsius. Take care in handling the hot water. Follow whatever safety precautions are relevant during this operation. Remove the seal from the hot water without damaging the seal.

The seal should be folded (fig. 1) taking care that the fold is not sharp enough to damage the seal permanently. Lubricate seal prior to insertion into the bore.

Figure 1 folding a U seal into the kidney shape

When folded, the seal can be inserted into the bore using two fingers (fig. 1). When released the seal will expand fully into the groove. Using fingers only, squeeze out any kink which may have formed during folding of the seal. Tools should not be used as this may damage the seal face. A finger can be inserted from either end of the bearing and the seal pushed back into its groove.

Once installed, the seal should be calibrated using either a greased calibration mandrel or the mating piston rod. The mandrel or piston rod should be inserted from the low-pressure side, i.e. the side opposite the step edge. Twisting of the rod or mandrel during insertion assists calibration. Lubricate the mandrel with silicone grease or equivalent.

Figure 2. Insert the seal the correct way relative to the pressure. This is massively important.

ALL FITTING TOOLS SHOULD BE NON-METALLIC. Consult factory if in doubt.

Fit the back-up ring by slipping it into the moulded counterbore in the U-seal, feeding it round and ensuring that it does not kink.

CHECK SEAL COMPATIBILITY WITH WORKING FLUID. Various seal compounds are available – please consult factory for advice.

Leave A Comment