Why use a 316 stainless manual hydraulic hand pump?

316 Stainless Steel manual hydraulic hand pumps are our speciality. Our 316 stainless steel pumps are widely used in applications where external corrosion due to the environment or alternatively internal corrosion of wetted parts in the hydraulic medium is an issue. These stainless steel pumps also have a very low magnetic permeability as might be required on a minesweeper or in towed arrays.

The corrosion resistance on a Micropac 316 (also described as 1.4404) stainless steel pump is substantially better than a 303 or 304 stainless steel unit.

Which industries and sectors need the enhanced corrosion resistance that 316 stainless offers?

Different users have different requirements.

Industries such as the offshore and process industries are often very concerned about external corrosion and specify hydraulics that has a long service life and will not be seized when it needs to be used. In these applications, 316 stainless and bronze external parts are important for them. An emergency shut down system on an actuator may not be used for many years and must be fit for purpose when it is eventually operated and not seized up.

Some industries such as the nuclear industry are very concerned about wetted parts. Some will require that wetted parts are only 316 stainless and polymer so that there is no risk of galvanic corrosion in an overall system. Many Engineers will not use an alloy or anodised alloy pump with water glycol (as used in automotive anti-freeze but also offshore hydraulics) due to corrosion anxieties in the longer term.

Check out what the specification says. If you do need very specifically to go to 100% 316 stainless and polymer, we can offer our PPS component hand pump for 316 system builders or the MU series basic 316 pump.

Some industries can live with 303 and 304 stainless, saving a substantial amount over using 316 stainless. The food industry often only requires 303 or 304 stainless that can be washed down to maintain hygiene. If you are comparing cost, ensure that you are checking like with like.

Sarum Hydraulics has developed specific units that meet the needs of particular applications. For example, the MT-3 series cartridge pumps use a 303 stainless steel body and barrel, a hard chromed 431 stainless piston rod and a hard anodised alloy clevis and swivel. These are used extensively in control systems in the offshore industry and meet their specific corrosion resistance requirements yet are substantially cheaper than our MT-6 cartridge pump units in 316/1.4404 stainless and bronze. This specific hand pump that addresses corrosion resistance in particular areas and has substantial cost benefits is widely used in the renewables sector, where there are a large number of identical installations such as wind farms. Contact us to discuss your application.

What stainless steel hydraulic hand pumps are in our Micropac range?

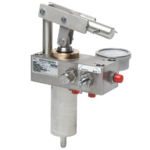

Our Micropac MW-3 316 Stainless Steel single speed, double acting stainless steel pumps with five models running up to 700 bar include rugged poppet and soft seat valves, wide fluid compatibility and excellent value for a quality pump.

Buy the MW series pump on a reservoir as an integral test or pumping set as our MP series. One part number describes a unit that is ready to use out of the box. Carry round a compact 5 or 10 litre unit or wheel round our neat 20 or 50 litre two wheel trolley sets.

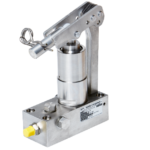

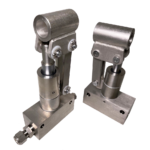

Our MD series two speed hand pump in 316 stainless and bronze offers a rugged, multi fluid hand pump in various versions up to 1000 bar. They use the same mounting interface as the MW units.

Our MT Cartridge Hand Pumps and MQ-CETOP Manifold Pumps are both available as 316 stainless units or versions using 303 stainless and hard anodised alloy clevises and swivels. They are compatible with industry standard manifolds for easy fitting and integration into your existing hydraulic system.

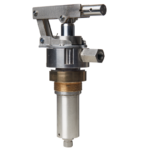

Our Micropac MB Drum Pump is made from 316 stainless steel and polymer to achieve long term corrosion resistance and a compatibility with a wide range of fluids.

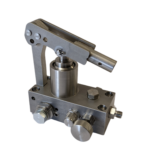

For unmatched corrosion resistance, our Micropac MU Hand Pump is made exclusively from 316 stainless steel with polymer for hydraulic systems in the most demanding applications.

For high external corrosion resistance and an “industry standard” footprint, our MG series hydraulic hand pump/reservoir uses our proven 316 stainless/1.4404 hand pump on a 316 stainless reservoir. Some of these units will retrofit in place of other manufacturers’ alloy and carbon steel units. An additional reservoir return or equaliser port simplifies installation. This equipment is used on subsea applications such as ESD systems and diving bell doors where alloy or carbon steel are unsuitable for safety and dependability.

316 Stainless steel system builders would use our 100% 316 stainless and polymer PPS hand pumps for their high integrity systems. We offer three models to 400 bar and multi fluid capability. The space envelope is very small and the handle swivel offers optimum operation for your particular installation. They would be piped into a system and a release valve, relief valve or gauge added as discrete components.

Our Micropac MFX offers a specialist single acting 50cc/50bar stainless 316 hand pump. Connections can be made on the pump body, allowing flush mounting.

Contact us to to discuss your 316 1.4404 stainless steel pump requirements.