How adding smart hydraulic design to seawater desalination and water treatment plant could just carry through a renewables revolution for fresh water from the sea.

The United Nations (UN) is very worried about fresh water in its World Water Development report of 2016. There are too many people on this planet and there is not enough water to go round.

What can be done? We know that engineering transforms lives, so the quest to cheaply produce freshwater from the sea for people who are thirsty has to be a mission deserving Holy Grail status. Desalination powered by renewables offers the potential of an unlimited supply of freshwater from the vast oceans of salt water that surround us and at minimal energy usage. Factor in that arid places by the sea are invariably sunny and subject to sea breezes and you could get excited at the prospects. As water hydraulic designers, we’re fascinated in the future of desalination. With 71% of the world’s surface covered by the oceans, that is a big resource. Even if you are unlikely to change the salinity of the sea overall, there is an environmental proviso on local increases in salt content and consequent damage to habitats. Yes, there is an environmental aspect to reverse osmosis desalination which can easily be missed along the way.

Will plummeting renewable costs make a difference?

The media tells us that the cost of photovoltaic (solar) panels has dropped by 80% over the past decade which has transformed their viability as a means of generating electricity. Even in the UK, electricity generation using wind turbines and photovoltaic (PV) panels reached 50% on some days in 2017 so could this be the green light for abundant fresh water in windy and sunny places by the sea? It is certainly changing the economics for desalination, but there is a bigger story and different challenges as well. Like any process plant, you have to buy the equipment for desalination, maintain it and pay to run it. Choose to run existing reverse osmosis desalination equipment on PV panels and the benefits are not so clear cut. Desalination plants are inherently expensive with high ongoing maintenance costs. Even if renewables remove the day-to-day energy operating cost, an investment in PV panels or wind turbines is required up front. And because the process is quite energy intensive, such an investment won’t be small.

So while the opportunity to “produce fresh water from the sea for free” is certainly seductive, let’s look at why it isn’t as easy as it seems.

Where we are now on reverse osmosis desalination?

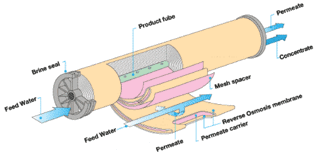

Reverse osmosis (RO) desalination has been around for years. In the 1970s, Filmtec (for many years part of Dow) developed spiral wound membranes constructed like a giant tea bag wound round a tubular former. That concept hasn’t changed. High-pressure seawater at 60 to 70 bar is pumped over the large surface of a semi-permeable polymer film with water molecules collected in the central tube and increasingly highly concentrated salt solution “solute” is removed. The membrane is mounted in a pressure vessel capable of working at 70 bar and although large membranes are available, vessels are often connected up in parallel or series to a larger number of smaller diameter units. Membrane production in itself is a big US dominated business, including manufacturers such as Dow, GE, Hydranautics and Koch.

Construction of a typical spiral wound membrane

The large range of membranes available

The process of producing fresh water from a reverse osmosis membrane is hard work. A litre of high-pressure seawater through a membrane at 70 bar might return 200cc or obtain 20% “recovery” of fresh water on a small plant. A massive reverse osmosis installation might achieve up to 400 to 500cc or 40% to 50% recovery. Inevitably, energy consumption is high.

A lot of water has to be pumped from the moment a plant is scaled up for groups of people rather than a handful of folks on a yacht or oil rig.

Just considering the volume of water that we all use every day and imagine producing fresh water for a town of 5,000 people. An industrial-sized plant is needed, not one the size of a rum shack on a beach, and operators are facing substantial investment — increased furthermore if the energy is to be provided by an array of wind turbines or PV panels to cut the day-to-day running costs.

Arrays of membranes are both expensive in respect of the cost of pressure vessels and also in consumables. Membranes last up to five years depending upon the level of pre-filtration, among other factors, but recovery drops off and the unit has to be swapped out. The pressure vessels that are essential to accommodate the membranes are more often than not composite, cutting mass and corrosion — but still expensive. In the hydraulics world, a large volume 100mm or 200mm diameter pressure vessel running at 70 bar is a serious safety and critical component. Swapping out membranes provides high maintenance costs and pressure vessels add to high capital costs on day one.

The arrays of membranes for a large plant are enormous.

Factor in these two costs of buying the pressure vessels and replacing membranes and then consider the cost of the hydraulics to produce the required flow rate of high-pressure seawater. Traditionally, large and quite exotic pumps are needed, as they have the ability to cope with highly corrosive seawater. Despite using high-cost materials, the seawater will take its toll on the system and maintenance is inevitable. So what can be done to use cheaper and less extravagant hydraulics that use less energy and last longer?

Driving down the total cost.

As hydraulic designers, we think that making the unit cheaper to own is essential. Even if you are using renewables to power the plant, you still have to pay for them on day one. Every reverse osmosis desalination unit needs some sort of piston pump, driven by an electric motor or internal combustion engine to pressurise the sea water up to 70 bar. Visionary designers would strive to get the capital cost down by cutting size and complexity as well as energy consumption and boosting service life. Back in the early days, units used piston pumps to pressurise the vessel and membrane up to 70 bar with the higher concentrate solute simply expelled over a relief valve. In principle, this wastes a massive amount of energy — which is simply being converted to heat.

What if the solute was used to turn a hydraulic motor that in turn assisted in turning the high-pressure pump motor instead of just wasting the energy through a relief valve? Alternatively, some of the pistons on a multi-piston swash plate or radial piston pump can be driven instead by the concentrated waste. These methods have provided basic energy recovery for years and cut dramatically the required energy input.

Traditional hydraulic piston pumps capable of extended life on sea water required exotic materials, 316 and duplex stainless steels, ceramics and polymers. That represents high capital cost, high mass and even then corrosion and maintenance costs are not solved. Can it be done differently? Sarum Hydraulics has always been intrigued by the Clark Pump on smaller reverse osmosis desalination units. A low-tech, low-pressure seawater pump both pushes the brine through the essential pre-filters (which remove muck) and, more importantly, feeds water to a water intensifier that generates the 70-bar, then cycles backwards and forwards, removing the more concentrated solute on the exhaust stroke. It doesn’t seem to scale up to big RO units, but it is a pointer to a way of dodging big extravagant piston pumps running at high speed. The GE Water “IPER” Pump for 1,000 cubic metre per-day scale plants is a slower piston pump with built-in energy recovery.

Change this for multiple pressure vessels, would there be a benefit of running lots of smaller pumps instead? Maybe, but they would all need their own electric motors which might not bode well for cutting the cost of the plant. That said, many low-tech pumps might end up being more durable than a few massive piston pumps.

Can technology continue to squeeze capital cost, maintenance cost and the energy requirement? At Sarum Hydraulics we think so. Pump materials that can better withstand corrosion would have a dramatic impact on viability for people who don’t have deep pockets. Electronic control systems that can eke out the power and keep the unit running at optimum efficiency will continue to improve. And consider improvements in membranes: graphene membranes continue to hold promise but aren’t easy to make. Jeffrey Grossman, a professor at the Department of Materials Science and Engineering at Massachusetts Institute of Technology (MIT) thinks that graphene membranes could cut energy consumption on seawater desalination by 15% and by up to 50% on brackish water. They also claim reduce biological fouling which in turn will keep efficiency higher and cut maintenance costs. Let’s see when graphene membranes actually hit the market.

Could a desalination plant ever become cheap tech?

At Sarum, can we ever envisage that a seawater reverse osmosis freshwater plant for a group of people can ever become a mass-market cheap commodity? Maybe, but the combination of high-pressures, nasty corrosive seawater and the need for bought-in membranes makes this a battle. A plant could theoretically be run on a day-to-day basis using cheap mass-market renewables, but expensive and exotic technology will still be required to buy and maintain the hydraulics. Might China further develop this technology and drive prices down? If we read that two thirds of their cities face a shortage of water in the future, could reverse osmosis technology become one of their “strategic technologies” to develop? China has many coastal cities with a high population concentration so seawater desalination plant must be a key technology for them, particular as we read that the Chinese Government expects to quadruple desalination over five years.

For many years, big seawater reverse osmosis plants have been showcase projects — such as those in the southern states of the US, The Gulf, Israel — and countless other regions where the lack of freshwater is holding back development. That initial big investment is the first hurdle but with an insatiable demand for water in the future world, big cities in wealthy countries will inevitably be queue-barging for these reverse osmosis desalination plants. If suppliers have plenty of wealthy customers, will poorer communities continue to suffer?

Don’t forget the scourge of brackish and dirty water

Beyond using renewables to power reverse osmosis systems to produce fresh water from the sea, two other equally challenging areas need addressing: brackish water and dirty water. Large parts of the world are faced with extracting water from an aquifer (or water table) which is salty or brackish. Excessive extraction from these water tables can even result in increasingly salty water, often devastating whole communities. Reverse osmosis systems are ideally suited to producing drinking water from brackish using similar plants to high-pressure seawater units. The size of the plant, pressure required and energy consumed are just way less. Instead of the 70 bar required for seawater, a typical brackish water RO unit reduces energy requirements to just 2 to 20 bar. This is still serious engineering, but if conditioning water from the aquifer, lots of smaller units are probably viable, opening the door to lower-cost equipment that is powered by smaller, renewable power units.

Fresh water can’t be taken for granted

Dirty water is tragic and amazingly prevalent in poor countries around the globe. Even where a community apparently has an unlimited source of fresh water from a local river, contamination in that water from human waste, animal waste or harmful industrial pollution may pose a real risk to health. As with desalination, only the richer nations can afford to pay for the plants to process dirty water or indeed tackle the scourge of bad water management. A similar story is true with processing effluent. Cities such as Singapore have been forced to invest massively in treating waste to counteract the day they find themselves short of water. A 2017 report from UNESCO suggests that cleaning up wastewater might be considered a top priority in the world, as it would provide massive reserves of drinking water. Close to home, London has been very successful in treating its waste water. But only as a result of huge investment and know-how built over many years.

Evaluating all the evidence and innovations to date, Sarum Hydraulics believes that producing freshwater from seawater has massive ongoing potential for improving the lives of those who can afford to pay for the plant and keep it running, but leaves vast swathes of the globe’s population exposed to the perils of dirty drinking water or salty brackish water. Just maybe the combined efforts of groundbreaking engineering material innovations, plummeting renewable energy costs and novel water hydraulics designs may come up trumps to bridge the gulf between the world’s growing populations and dwindling water supplies.

And yes, cheap access to fresh water produced from the sea is indeed a Holy Grail. Once you have got over the tantalising prospect of running it on renewables, you do however need to move on to lowering the capital cost and cutting the burden of maintenance on reverse osmosis desalination plant.

Sarum Hydraulics knows its marine hydraulics and water hydraulics but other than selling Micropac pumps for pressure testing Reverse Osmosis systems, we haven’t made our mark on desalination. Talk to us on 0044 1722 328388 or contact pumpsales@sarum-hydraulics.co.uk .

Additional Information:

A world short of water http://unesdoc.unesco.org/images/0024/002440/244041e.pdf

Graphene reverse osmosis membranes hold great promise http://news.mit.edu/2015/desalination-gets-graphene-boost-jeffrey-grossman-1102

RO desalination is big in Asia http://www.waterworld.com/articles/wwi/print/volume-25/issue-6/regional-spotlight-asia-pacific/market-report-developing-desalination.html

Chinese water production using desalination. https://www.bloomberg.com/news/articles/2015-04-09/china-embraces-desalination-to-ease-water-shortages

Cleaning up wastewater as a priority?

http://unesdoc.unesco.org/images/0024/002475/247552e.pdf

Are there risks to local marine habitats?

https://www.scientificamerican.com/article/the-impacts-of-relying-on-desalination/

Leave A Comment